Vacuum Release Box With Clips

2024.05.27 / By admin

Meta Descriptions

CrysPack offers vacuum release box with clips for easy and secure packaging. Trust our solutions for efficient storage and transport.

Seamless Automation: Integrating Vacuum Release Box with Clips for High-Volume Operations

Explore the transformative impact of CrysPack’s Vacuum Release Box with Clips on delicate device management in chip manufacturing. Experience tailored solutions, seamless automation integration, and versatile configurations for unmatched protection and efficiency.

Introducing the Vacuum Release Box with Clips by CrysPack: Safeguarding Fragile Devices

1.1 Versatile Protection: Ensuring Safety Every Step of the Way

In the fast-paced world of chip manufacturing, the need for reliable and robust solutions to handle delicate components is paramount. CrysPack’s Vacuum Release Box with Clips steps up to this challenge, offering a unique solution that securely holds fragile devices without the need for traditional pockets. This innovative approach is especially crucial during transportation and processing stages, where the slightest mishandling can result in irreparable damage to components like bare die.

1.2 Customized Solutions: Tailored to Meet Industry Demands

In the chip industry, one size does not fit all. Each manufacturing process comes with its own set of requirements and challenges. CrysPack understands this variability and has designed its technology to offer customizable solutions that cater to the specific needs of the industry. Whether it’s adjusting for the size of the devices, the level of fragility, or the preferred handling method, the Vacuum Release Box with Clips can be adapted to meet a diverse range of demands.

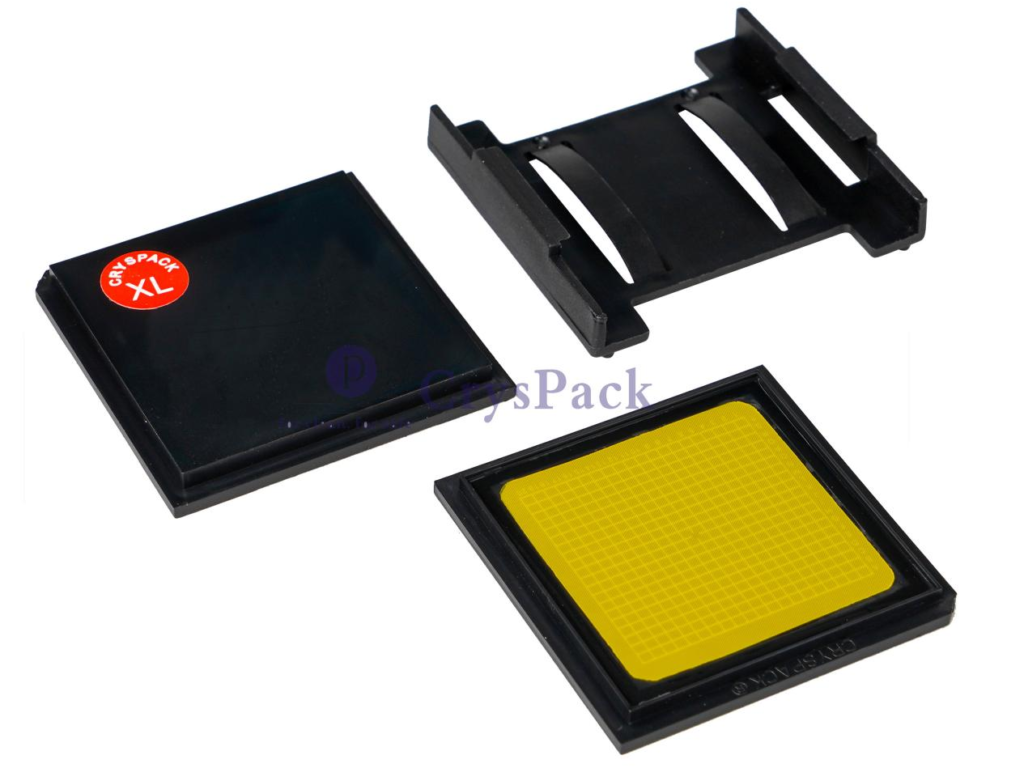

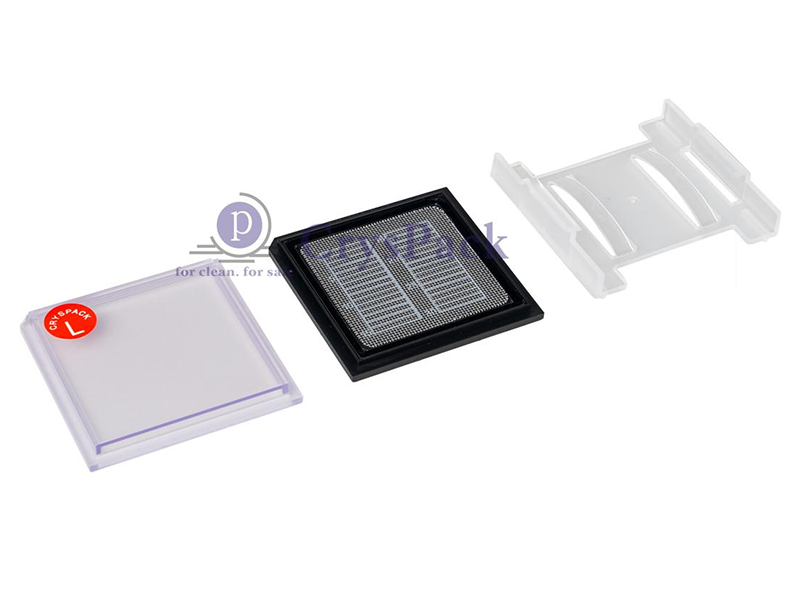

Understanding the Innovative Design: A Closer Look at CrysPack’s Technology

2.1 The Heart of the Solution: Gel or Vertec™ Film Membrane

At the core of CrysPack’s Vacuum Release Box with Clips lies an innovative design that combines a proprietary Gel or non-silicone Vertec™ film membrane with a mesh material. This combination ensures that fragile components are securely held in place throughout the transportation and processing stages. The membrane acts as a protective barrier, preventing any unwanted movement or damage to the devices housed within the tray.

2.2 Securing Fragile Components: Applying Vacuum to Release

The beauty of CrysPack’s technology lies in its simplicity and effectiveness. To release the components from the tray, all it takes is the application of vacuum to the underside of the tray. This triggers the release mechanism, allowing for easy and seamless removal of the devices without any risk of damage. This innovative approach streamlines the handling process, reducing the risk of errors and ensuring the safety of the components at all times.

Exploring the Versatility of CrysPack’s Vacuum Release Box with Clips

3.1 Tailoring Solutions for Specific Needs: Size, Fragility, and Handling Method

In the dynamic world of chip manufacturing, versatility is key. CrysPack’s Vacuum Release Box with Clips offers a range of customizable options to suit a variety of needs. Whether it’s adjusting for the size of the devices, the level of fragility, or the preferred handling method, CrysPack’s technology can be tailored to meet specific requirements. This versatility ensures that manufacturers can find the perfect solution to safeguard their delicate components.

3.2 Streamlining the Manufacturing Process: High-Volume Pick and Place Applications

Efficiency is the name of the game in chip manufacturing, and CrysPack’s Vacuum Release Box with Clips delivers. Designed for high-volume pick-and-place applications, this technology seamlessly integrates into automated processes, optimizing productivity and throughput. By securely holding fragile devices during transportation and processing stages, CrysPack’s solution minimizes the risk of errors and ensures a smooth manufacturing process from start to finish.

Unlocking Specialized Applications: The Vacuum Release Tray’s Unique Capabilities

4.1 Meeting the Needs of Fragile Devices

In the intricate world of chip manufacturing, where precision is paramount, the Vacuum Release Tray emerges as a specialized solution catering to the most delicate of components. Its ability to handle extremely fragile or thin devices sets it apart, providing a level of protection that conventional trays may struggle to match. Whether it’s safeguarding bare die or handling ultra-thin substrates, the Vacuum Release Tray excels where other solutions fall short.

4.2 Enhancing Reliability in Fragile Device Handling

The specialized applications of the Vacuum Release Tray extend beyond mere protection. Its design ensures that fragile devices are securely held in place throughout the transportation and processing stages, minimizing the risk of damage or mishandling. By providing a stable and secure environment for delicate components, the Vacuum Release Tray enhances reliability in fragile device handling, safeguarding valuable assets throughout the manufacturing process.

Seamless Integration with Automation: Maximizing Efficiency in Chip Manufacturing

5.1 Optimizing High-Volume Pick and Place Applications

Efficiency is the cornerstone of modern chip manufacturing, and the Vacuum Release Tray is engineered to deliver. With a focus on high-volume pick and place applications, this technology seamlessly integrates into automated processes, streamlining operations and maximizing throughput. By automating the handling of fragile components, the Vacuum Release Tray reduces the risk of errors and accelerates the production cycle, driving productivity to new heights.

5.2 Facilitating Efficient Handling and Processing

The design of the Vacuum Release Tray is optimized for automation, with features that facilitate efficient handling and processing. Its compatibility with robotic pick and place systems ensures smooth and precise operation, minimizing downtime and maximizing efficiency on the production floor. Whether it’s loading substrates onto processing equipment or transferring components between workstations, the Vacuum Release Tray streamlines the handling process, empowering manufacturers to meet the demands of a fast-paced industry.

Configurability and Compatibility: Tailoring Solutions to Industry Needs

6.1 Flexibility in Tack Levels and Tray Sizes

The Vacuum Release Tray offers a level of configurability and compatibility that caters to diverse industry needs. From different tack levels to tray sizes based on JEDEC standards, it provides flexibility and adaptability to suit a range of applications. Whether manufacturers require ultra-low tack for delicate substrates or high tack for secure component retention, the Vacuum Release Tray can be customized to meet specific requirements, ensuring optimal performance in any setting.

6.2 Diverse Options for Varied Preferences

In addition to its configurability, the Vacuum Release Tray is available in a variety of materials and configurations to accommodate diverse preferences and requirements. From transparent trays that offer visibility and inspection capabilities to conductive black trays that provide protection against electrostatic discharge, the Vacuum Release Tray caters to a spectrum of needs. Its compatibility with transparent antistatic options further enhances its versatility, ensuring compatibility with a wide range of manufacturing environments.

Conclusion: Elevating Chip Manufacturing with CrysPack’s Vacuum Release Box with Clips

In the competitive world of chip manufacturing, every detail matters. CrysPack’s Vacuum Release Box with Clips offers a cutting-edge solution that addresses the industry’s need for reliable, customizable, and innovative handling solutions. From its versatile protection capabilities to its customizable design, CrysPack’s technology is poised to revolutionize the way fragile components are handled during transportation and processing stages. With CrysPack’s Vacuum Release Box with Clips, manufacturers can rest assured knowing that their delicate components are in safe hands.