Cryspack’s Sticky Boxfor Component Retention and Organization

2024.11.26 / By hqt

Grabbing Your Attention: Why the Sticky Box is Revolutionizing Industries

Have you ever struggled to keep your workspace organized, components in place, and your production line efficient? The answer to these challenges may lie in an innovative product designed to secure, organize, and streamline the assembly process across multiple industries: Cryspack’s Sticky Box. In a market where efficiency, durability, and automation compatibility are highly valued, the sticky box is emerging as a powerful solution for manufacturers and engineers alike.

This blog dives deep into Cryspack’s sticky box, exploring its unique features, market trends, and the benefits it brings to modern production environments. We will also touch on market data for 2023, future projections, and Cryspack’s other leading products, including the membrane box, gel sticky box, and vacuum release trays. Let’s explore how Cryspack is setting the standard for component retention and organizational tools.

Innovative Features of Cryspack’s Sticky Box: Engineered for Excellence

Adjustable Stickiness: A Tailored Approach to Component Retention

One of the standout features of Cryspack’s sticky box is its adjustable stickiness. Unlike traditional adhesive solutions that may apply an excessive or insufficient amount of adhesive, the sticky box allows users to control the level of adhesion based on the size, shape, and weight of components. This flexibility makes it an ideal solution for retaining various materials, from lightweight to heavier items, ensuring safe transport and storage without leaving residue.

For industries where delicate or intricate components require secure retention, the sticky box provides a customized and dependable solution. The adhesive transfer tape used can be adjusted with ease, allowing users to achieve the perfect balance between security and accessibility.

Automation Compatibility: Ready for Modular Production Lines

Cryspack has designed the sticky box with the future of manufacturing in mind. It is compatible with automated production lines, making it a valuable asset for companies aiming to enhance productivity. By ensuring automation compatibility, Cryspack has aligned its product with the needs of industries that require a seamless and reliable integration of component retention systems into modular production setups.

Manufacturers benefit from reduced manual handling, which not only cuts costs but also minimizes the risk of human error. As automation in manufacturing grows, Cryspack’s sticky box is an ideal choice for companies aiming to optimize their workflows with an easy-to-implement, durable solution.

Functional Design Features: Form Meets Function in Every Layer

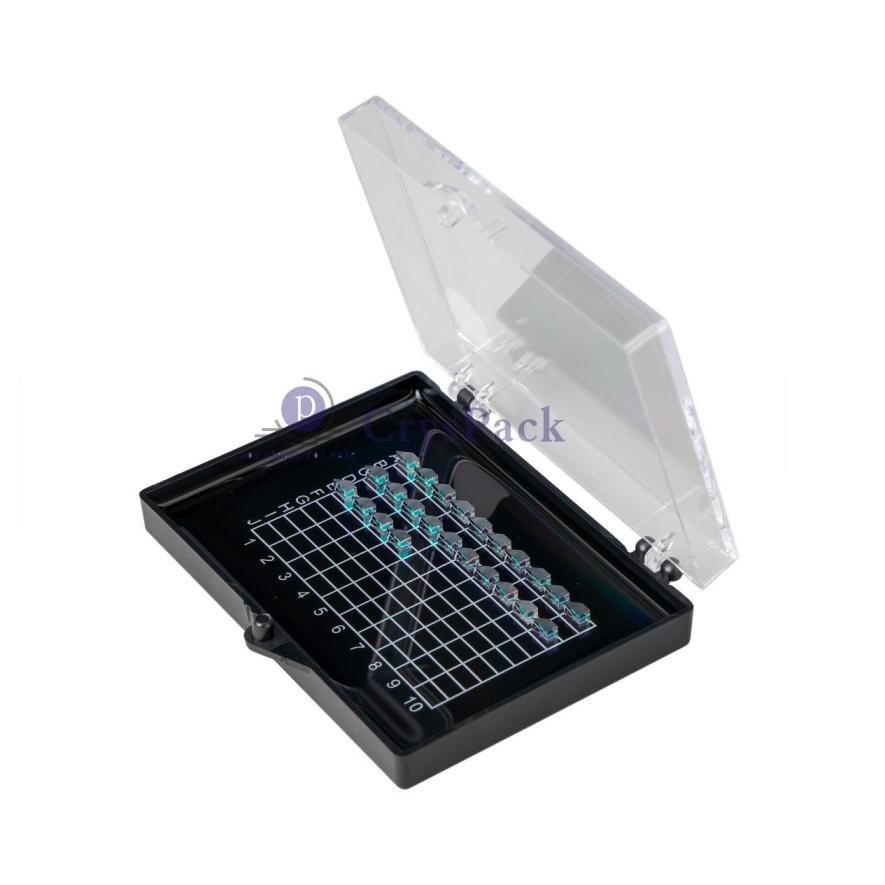

Sized to Perfection: Compact and Clutter-Free

Space efficiency is a priority in any production or storage setting, and Cryspack’s sticky box meets this need with its compact design. Each mold is thoughtfully designed to hold the right amount of material, keeping items organized and maximizing available space in refrigerators, freezers, or assembly lines.

For companies managing inventory or components in limited storage spaces, the sticky box’s streamlined design eliminates clutter. This feature ensures that production facilities remain organized, contributing to a smoother workflow and a more manageable inventory system.

Slim & Sleek: Optimized for System Space Utilization

In addition to its compact design, the sticky box boasts a slim and sleek profile. This enables users to make full use of their available system space, whether in storage units, assembly lines, or transportation containers. The slim design facilitates easy stacking and storage, allowing users to maximize their space without compromising on the safety or accessibility of their components.

Cryspack’s thoughtful engineering means that companies can depend on their sticky boxes to deliver efficient organization without adding bulk, ensuring that each item stays securely in place within an optimized footprint.

Quality Materials and Transparency: Built to Last, Easy to Inspect

High-Quality Materials: Built for Durability

Cryspack is committed to providing products that stand up to the demands of industrial use, and the sticky box is no exception. Constructed from high-quality materials, this product is engineered to withstand wear and tear over extended periods. For industries where equipment durability is essential, Cryspack’s sticky box delivers long-lasting performance that users can rely on for years.

The robust materials used in the construction of the sticky box allow it to endure various environmental factors, making it an ideal solution across industries and environments. From temperature fluctuations to physical impact, Cryspack’s sticky box is built to endure.

Transparent Choices: Easy Inspection and Real-Time Monitoring

Cryspack understands the importance of transparency in component storage. The sticky box’s design allows for visual transparency, enabling quick inspection and real-time monitoring of components. This transparency is particularly useful in automated or high-paced environments where users need to verify the contents without disrupting operations.

Whether in electronics, pharmaceuticals, or manufacturing, the ability to see and assess component status immediately is a key advantage. Cryspack’s sticky box ensures that users can perform visual inspections at a glance, improving workflow efficiency and minimizing the need for frequent handling.

Maximizing Workflow Efficiency with CrysPack Multi-Purpose Plastic Tray

Multi-Purpose Design: Supporting Diverse Industrial Needs

The sticky box isn’t the only solution Cryspack offers. Their multi-purpose plastic trays are also gaining attention as a versatile and flexible solution for various industries. Designed to retain components securely while facilitating rapid assembly processes, these trays are ideal for companies looking to enhance workflow efficiency and streamline operations.

Cryspack’s multi-purpose trays, like the sticky box, align with the needs of modern production environments, offering compactness, durability, and compatibility with automated systems. These products support industries that require quick and reliable solutions for component handling and storage.

More from Cryspack: Innovative Component Retention Solutions

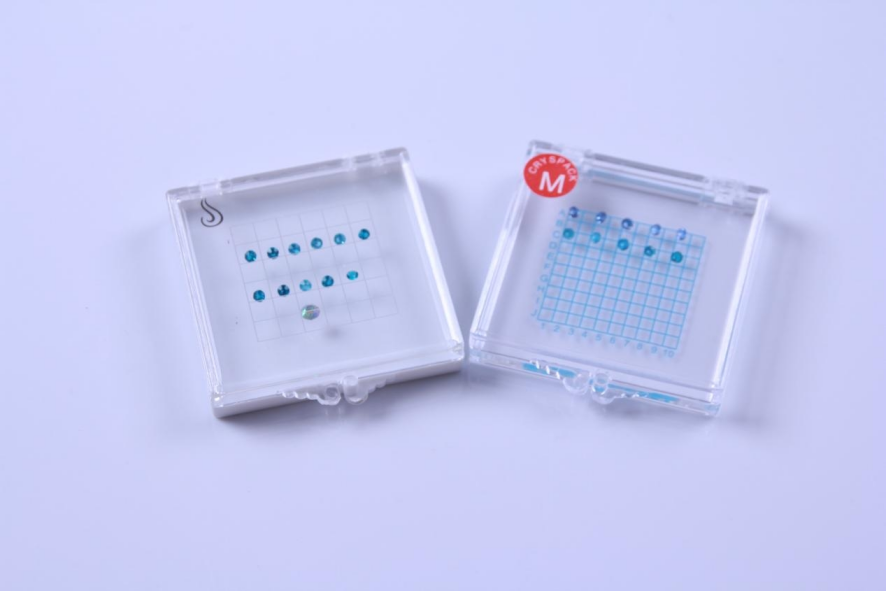

Membrane Boxes, Gel Sticky Boxes, Vacuum Release Trays, and More

Cryspack doesn’t stop at sticky boxes and multi-purpose trays. Their product lineup includes membrane boxes, gel sticky boxes, vacuum release trays, and vacuum release boxes. Each of these solutions is designed with the same attention to detail and quality as the sticky box, providing customizable solutions to meet specific industry needs.

From protecting sensitive electronic components to simplifying inventory management, Cryspack’s range of products addresses unique challenges across sectors. These additional offerings highlight Cryspack’s dedication to innovation and its ability to cater to diverse market demands.

OEM and ODM Services: Tailored Solutions for Every Project

Cryspack goes a step further by providing OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services, allowing clients to obtain products that are customized to their exact specifications. With a team of professional engineers, Cryspack delivers first-class technical support and customer service, ensuring that each client’s unique project requirements are met with precision.

Why Choose Cryspack? Leading the Way in Component Retention Solutions

Cryspack’s sticky box and other component retention solutions are redefining efficiency, organization, and automation compatibility in the modern industrial landscape. From its adjustable adhesive properties to its durable materials and space-saving design, the sticky box is a prime example of how Cryspack meets the evolving needs of its clients.

Backed by high-quality engineering and customer-centered services, Cryspack’s offerings continue to gain traction across industries, setting a new standard for component retention solutions. For any company looking to optimize its workflow and ensure seamless, efficient component management, Cryspack provides the technology and expertise to support its goals.

In a rapidly growing market, Cryspack’s sticky box stands out as a powerful tool for those who value quality, efficiency, and flexibility. Whether it’s automation-ready trays or customizable solutions, Cryspack remains at the forefront of industrial innovation.