The Breakthrough Vacuum Release Box for Enhanced Photonics Chip Performance

2025.03.20 / By hqt

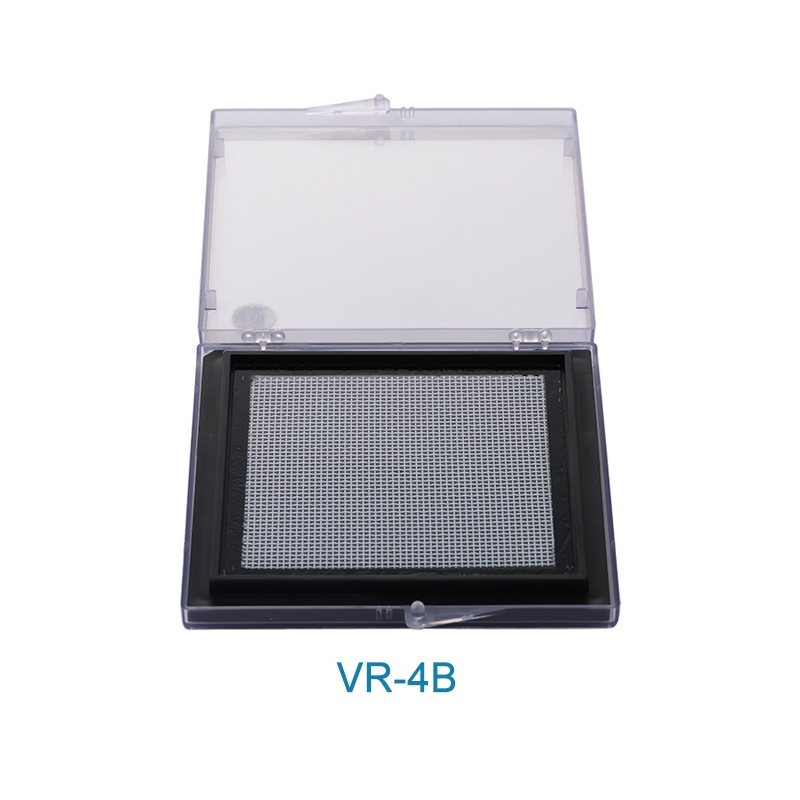

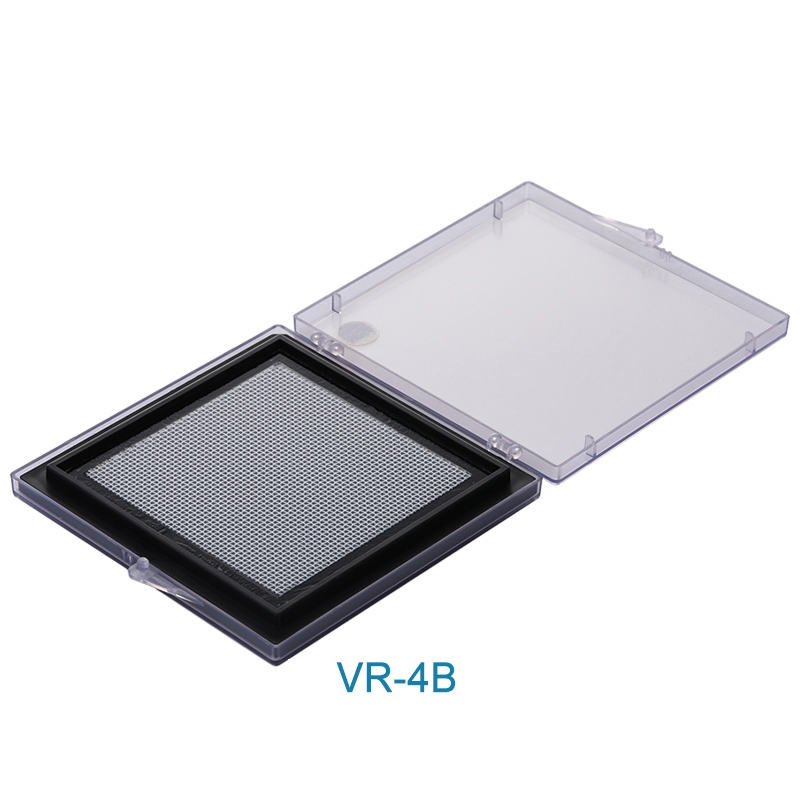

Innovation plays a key role in improving photonics chip performance. As the demand for better technology grows, new methods are being developed to meet these needs. One such method is vacuum release box technology. CrysPack has introduced a new solution for packing delicate devices, including photonics chips. This solution is called the Vacuum Tray. It is used in industries like semiconductors, optoelectronics, and telecommunications. The vacuum release box is designed to protect fragile optics, ensuring their safety during transport and handling. This new development will significantly impact the industry by offering a reliable way to prevent damage to delicate components. What makes the vacuum tray different from older packing methods? How does it enhance the overall performance of the technology it supports?

The Need for Improved Photonics Chip Performance

Growing Demand for Faster and More Efficient Chips

The need for better photonics chips is increasing. Many industries rely on fast and efficient chips. These chips help in areas like communication, computing, and healthcare. Faster chips can process more data and work more effectively. This helps meet the growing demands for technology.

Challenges Faced by Current Chip Technologies

Current chip technologies face some problems. Chips can be fragile and are often easily damaged during production. Also, they can suffer from overheating and signal loss. These issues make it difficult to improve their performance. The demand for better solutions is high.

The Role of Vacuum Technology in Overcoming Challenges

Vacuum technology plays a key role in solving these problems. It creates a safe environment for chips by removing oxygen and moisture. This helps prevent damage. Vacuum technology also helps chips stay cooler. This reduces the risk of overheating and improves performance.

How the Vacuum Release Box Works

Vacuum Sealing Technology

The vacuum release box uses vacuum sealing technology. This creates an environment without oxygen and moisture. It protects optics from damage and contamination. The technology ensures a secure environment during transport and handling.

Superior Product Protection

The vacuum release box offers the best protection for delicate products. It keeps the components safe from damage, contamination, and static. The box provides permanent protection to ensure the optics stay in perfect condition. This helps improve the overall performance of the components.

Durable and Impact-Resistant Material

The vacuum release box is made from high-strength plastic. This material is durable and can withstand impacts. It ensures that components are handled quickly and safely. This makes the box a reliable solution for protecting fragile optics.

Non-Contact Protection

One of the key features of the vacuum release box is non-contact protection. The optics inside the box are suspended within the vacuum. This minimizes any contact with the sides of the box. As a result, the risk of damage is reduced. The components are well-protected, ensuring they remain safe during handling.

Benefits for the Photonics Industry

Enhanced Chip Performance and Reliability

The vacuum release box improves the performance of photonics chips. It helps prevent damage that can happen during transportation and handling. As a result, the chips work better and last longer. The box ensures they stay safe and secure, making the chips more reliable. This leads to better performance in various photonics applications.

A Clear Lid for Easy Product Management

One key feature of the vacuum release box is its clear lid. This allows users to see the contents inside. The clear lid helps to easily manage the products and track inventory. This is important for industries that need to keep an eye on stock levels. It also ensures that the right components are being used without any confusion. This feature simplifies the process of managing fragile optics.

Increased Scalability for Photonics-Based Applications

The vacuum release box allows for greater scalability in photonics-based applications. Its design makes it easy to pack more components without sacrificing safety. This helps meet the growing demand for photonics chips and other optical products. With this technology, companies can scale up their production and meet customer needs more effectively.

Applications of the Technology

Semiconductor Packaging

The vacuum release box is ideal for semiconductor packaging. It keeps fragile semiconductor components safe from scratches. This is important during transport and handling. The box ensures that the components arrive in perfect condition and work as intended.

Optical Storage

The technology is also useful for optical storage components. It protects optical parts used in optical instruments. These components are often delicate and can be easily damaged. The vacuum release box ensures they are safe and secure during transport.

Optoelectronics Packaging

Optoelectronic devices often contain sensitive optical components. The vacuum release box is perfect for packaging these components. It prevents damage during shipping and handling. This ensures that the components remain in excellent condition when they reach their destination.

Telecommunication Equipment Packaging

In the telecommunication industry, optical components are critical for the performance of equipment. The vacuum release box helps protect these fragile parts. It safeguards them from damage during transport, ensuring the equipment functions as expected once it is set up.

Medical Device Packaging

Medical devices often contain delicate optical components. These parts are crucial for the proper functioning of the devices. The vacuum release box is used to protect them during transportation and storage. It ensures that the medical devices reach their destinations safely and ready for use.

Why Choose CrysPack

Innovative Solutions for Safe Handling and Shipping

CrysPack has developed innovative solutions for shipping and handling delicate technologies. More than 1000 active customers trust CrysPack’s products for their fragile components. The company is known for creating safe, reliable packaging that protects sensitive materials.

High-Quality Management and Customer Satisfaction

CrysPack’s quality management system ensures the best products and services. The company’s research and development team is always working on new ideas. Our fast-response sales network provides customers with a smooth purchase and use experience. Customers can expect quick and efficient support when needed.

CrysPack‘s Commitment to Quality

CrysPack is dedicated to ensuring the highest standards of quality. If a product is faulty, CrysPack will inspect it and offer free replacements. The company aims to be your first choice for shipping and handling fragile and valuable products. Our goal is to provide reliable solutions for every customer.

Protect Your Photonics Chips with CrysPack‘s Vacuum Release Box

CrysPack’s vacuum release box keeps your photonics chips safe. It offers the best protection during transport and handling. The box uses vacuum sealing to prevent damage. Your components will stay safe from moisture and oxygen. The clear lid lets you easily check your inventory. It also helps keep things organized. Choose CrysPack to ensure your photonics chips are handled with care. Don’t risk your valuable products. Trust CrysPack for safe, reliable packaging. Ready to protect your components? Contact CrysPack today!