Boosting Semiconductor Production: The New Vacuum Release Tray for Chips

2025.03.22 / By hqt

The vacuum release tray plays a key role in semiconductor production. It helps improve how chips are handled during manufacturing. By offering better safety, the tray reduces the risk of damage. Handling chips carefully is crucial for ensuring their quality.

CrysPack created a new way to pack fragile or thin devices, like semiconductor chips. This method uses a vacuum tray. The tray is now widely used in industries like semiconductors, optoelectronics, and telecommunications. CrysPack’s plastic optics boxes ensure maximum safety for delicate devices during transport and handling. The company’s high-quality management system, strong R&D team, and quick sales support make the purchasing process easy and reliable.

Want to know how this innovation boosts chip production? Let’s dive in!

The Technology Behind the Tray

How the Vacuum Release System Works

At the core of the vacuum release tray’s functionality is advanced vacuum sealing technology. This system creates a controlled environment that is free from oxygen, moisture, and other potentially harmful contaminants. When semiconductor chips are handled, they can be highly sensitive to environmental factors like dust, humidity, and static electricity, which can cause significant damage. The vacuum seals the chips in place, creating a stable environment that protects them during the handling, transport, and production stages. The absence of external air reduces the chance of oxidation, corrosion, or contamination, ensuring the chips remain in optimal condition throughout the manufacturing process.

Key Design Features Ensuring Chip Safety

The design of the vacuum release tray is carefully crafted to offer maximum protection for delicate semiconductor chips. The tray is constructed from high-strength, impact-resistant plastic that can withstand the rigors of industrial use. This durable material ensures that the tray can be used repeatedly without breaking down, offering long-term reliability. Additionally, the vacuum system within the tray keeps the chips suspended in mid-air, reducing the risk of direct contact with the surface. This unique feature significantly minimizes the chances of scratches, cracks, or other forms of mechanical damage that can occur during handling. The vacuum release tray is designed with precision to ensure that chips are kept stable and safe at all times.

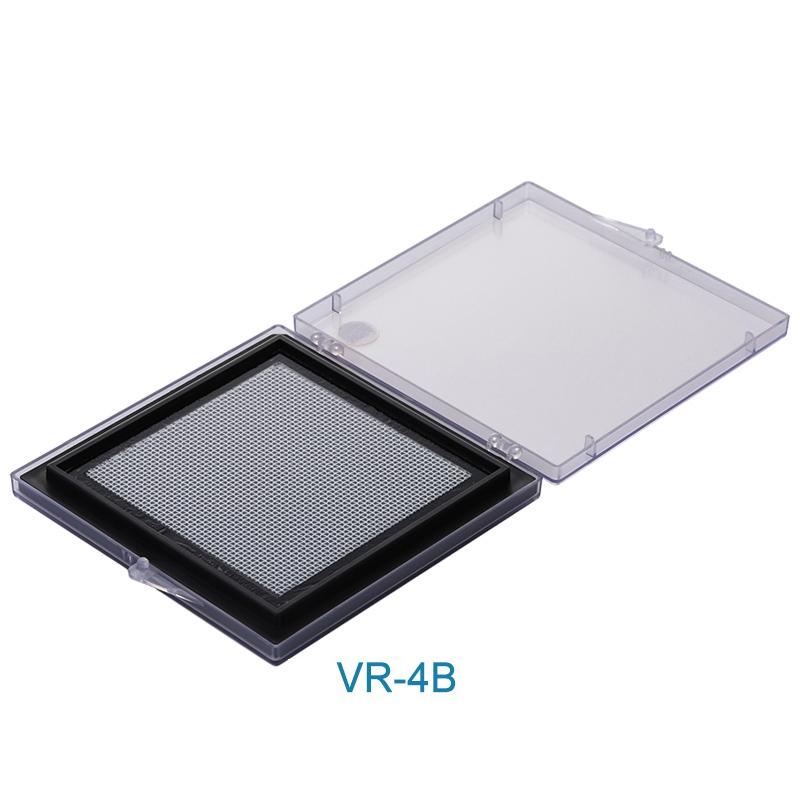

Visible Design for Easy Monitoring

Another essential feature of the vacuum release tray is its clear lid, which provides full visibility of the contents inside. This transparent design allows operators to quickly monitor the chips and ensure they are properly secured without having to open the tray. The clear lid also facilitates easy tracking of inventory, making it simpler to manage large quantities of semiconductor chips throughout the production process. This added layer of visibility helps maintain high-quality control standards and reduces the risk of errors or overlooked components.

Impact on Semiconductor Production Efficiency

Reduced Production Time and Faster Output

The vacuum release tray contributes significantly to improving the speed of semiconductor production. By reducing the amount of time spent on manual handling and adjusting components, the tray accelerates the production process. With chips held securely in place, operators can quickly release them without the need for intricate adjustments or delicate handling. This results in faster turnaround times, which ultimately increases output and allows for more efficient manufacturing. The overall speed of production is enhanced, making it possible to meet higher demand while maintaining product quality.

Minimizing Human Error in Chip Handling

The automation features integrated into the vacuum release tray play a crucial role in minimizing human error during semiconductor handling. Manual handling often involves a degree of risk, as the delicate nature of semiconductor chips makes them prone to accidental drops, misplacement, or incorrect positioning. The vacuum release tray eliminates much of this risk by securely holding the chips in place, reducing the potential for mistakes. The system ensures that every chip is handled in precisely the right way, improving the consistency and quality of the production process. This results in fewer defects and more uniform products, which is critical for maintaining high standards in semiconductor manufacturing.

The Role of Automation in Streamlining Processes

The integration of automation in the vacuum release tray’s design streamlines production processes by reducing manual labor. By automating aspects of chip handling, the tray enhances workflow efficiency and minimizes delays caused by human intervention. Automation reduces the time spent on repetitive tasks, such as loading and unloading chips, allowing operators to focus on more complex tasks that require their expertise. As a result, production lines can operate at higher speeds with fewer interruptions, contributing to greater overall productivity.

Enhancing Chip Quality and Reducing Damage

Prevention of Scratches and Cracks During Release

One of the primary benefits of using the vacuum release tray is its ability to prevent damage to the semiconductor chips. When chips are handled manually, the risk of scratches, cracks, or other surface damage is high, especially given their delicate nature. The vacuum system, however, suspends the chips in mid-air, reducing direct contact with the tray surface. This prevents chips from being scratched or cracked during the handling process, ensuring that they remain in pristine condition. The tray’s design reduces friction and physical interaction, which is especially important for maintaining the integrity of chips with sensitive components like optical lenses or microelectronics.

Impact on Chip Longevity and Functionality

Proper handling of semiconductor chips is vital for their longevity and performance. The vacuum release tray not only protects chips during handling but also helps maintain their functionality over time. By minimizing exposure to environmental factors and physical damage, the tray ensures that the chips remain intact and perform optimally throughout their lifespan. This protection is crucial for the long-term viability of semiconductor products, as any damage during production can negatively impact the chip’s functionality, leading to early failures or suboptimal performance in their end applications.

High Precision in Handling Delicate Semiconductor Chips

The vacuum release tray offers unparalleled precision in chip handling. With its vacuum system gently securing the chips in place, it ensures that even the most delicate semiconductor components are handled with the utmost care. Precision is particularly important in semiconductor manufacturing, where even the smallest error can result in a significant loss of quality or yield. The vacuum release tray eliminates the need for excessive force or manual adjustment, providing an exact and secure fit for each chip. This level of precision is essential in maintaining the high standards required for semiconductor production.

Cost Benefits for Manufacturers

Superior Product Protection

The vacuum release tray offers substantial protection for semiconductor chips, safeguarding them against damage, contamination, and environmental factors. This protection helps prevent costly defects that could otherwise lead to rework or loss of product. By ensuring that the chips arrive at their destination in perfect condition, manufacturers can avoid expensive replacements and reduce waste. This contributes to overall cost savings and improves the efficiency of the production process.

Saves Time While Loading, Unloading, and Transportation

The vacuum release tray is designed for efficiency in loading, unloading, and transportation. Its intuitive design speeds up the movement of chips between stages of production, reducing downtime and eliminating the need for complex handling procedures. This improvement in logistics saves time and helps streamline the production flow, resulting in higher overall productivity. By simplifying the process, manufacturers can achieve more output with fewer resources, contributing to better cost management.

Economic Advantages for Large-Scale Production

For manufacturers operating on a large scale, the vacuum release tray offers significant economic advantages. The reduction in defects and damage translates directly into fewer resources spent on repairs, replacements, and rework. Additionally, the faster pace of production helps meet higher demand without compromising quality. These factors combine to improve profitability, making the tray a valuable investment for large-scale semiconductor operations.

Customizable Retention Levels

The vacuum release tray is highly adaptable, with customizable retention levels that can be adjusted to accommodate different sizes and weights of components. This versatility makes it an ideal solution for a wide range of semiconductor chips and other delicate products. Whether dealing with small, lightweight chips or larger, heavier components, the tray can be tailored to provide the right amount of retention to ensure optimal handling.

How the Tray Supports Industry Sustainability

Reduction in Material Waste and Resource Efficiency

The vacuum release tray plays a significant role in reducing material waste. By securely holding chips in place, it reduces the need for additional packaging, which helps cut down on unnecessary resource consumption. The tray’s durability and ability to minimize damage also help prevent waste from defective products, making the production process more efficient and resource-conscious.

Helping Meet Industry Sustainability Goals

As sustainability becomes an increasingly important focus in the semiconductor industry, the vacuum release tray contributes to meeting these goals. By improving efficiency, reducing waste, and enhancing chip protection, it supports environmentally friendly manufacturing practices. Companies that implement the tray can help lower their environmental impact, contributing to their sustainability efforts.

Contribution to Greener Manufacturing Practices

The tray supports greener manufacturing practices by reducing the need for excessive packaging materials, minimizing waste, and enhancing overall production efficiency. This aligns with the growing industry shift toward more eco-friendly practices. By adopting the vacuum release tray, manufacturers can move closer to their sustainability targets while also improving their operational efficiency.

Final Words

Looking to enhance your semiconductor production? The vacuum release tray provides protection, efficiency, and cost savings. It minimizes chip damage and accelerates handling, ensuring precise control for better chip quality. Plus, it saves time and money, making large-scale production more manageable. Curious about how it can benefit your production line? Discover how this straightforward innovation can elevate your results today! Don‘t delay – optimize your production process now!