DETAILS*

Silicon Wafer Chips Box Features

- Dynamic Retention: Patented vacuum technology ensures that your devices are secured during transport and handling, while still providing quick access when necessary.

- Customizable Configuration: Select from multiple tray sizes, retention levels and mesh geometries to closely align your wafer size needs at the proper sensitivity.

- Exceptional Particle Protection: The isolation provided by our vacuum technology offers improved protection from particulates, maintaining product purity.

- Increased Efficiencies: Through the ability to place and retrieve parts more smoothly, our process is rendered faster (shorter production cycles) with increased productivity levels as less human infrastructure/labor time is involved.

- Data-Driven Design: Our Silicon Wafer boxes has been developed through significant testing and analysis to ensure a very high quality, performance & reliability.

Silicon Wafer Chips Box Applications

- Semiconductor Manufacturing: Its robust design protects silicon wafers throughout its production processes.

- Research and Development (R&D): Ideal case for keeping sensitive prototypes and research wafers safe.

- Chip Transport: You can safely transport the chips, ensuring the safe delivery of high-value parts.

- Storage and Archival: It is a perfect box to store the silicon chips. It mainly extends its life, to keep the semiconductor valuable for a year.

- Component Handling: Simple and quick means of moving wafers without contact or damage in cleanroom areas.

Silicon Wafer Chips Box Advantages

- Shielding Yields: Reduces cell breakage, contamination, and device degradation for higher yields and reduced rework.

- Operational Efficiency: Efficient workflows and minimal handling time ensure productivity increases in both quality and cost savings.

- Risk Management: It saves from huge product loss caused by transport and handling damage.

- Improved product quality: Ensures device integrity to guarantee peak performance and reliability.

- Competitive Advantage: Set your business apart by offering a start-to-finish packaging solution that showcases the quality and innovation of your business.

VR box configurations

1. 2 inch/4 inch/ 5 inch/ 6 inch tray size based on JEDEC standard.

2. Wide range of retention levels: XL, L, M, H, HH

3. A wide range of mesh geometries (16, 33, 76, 103, 137, and 195)

4. Print patterns can be customized

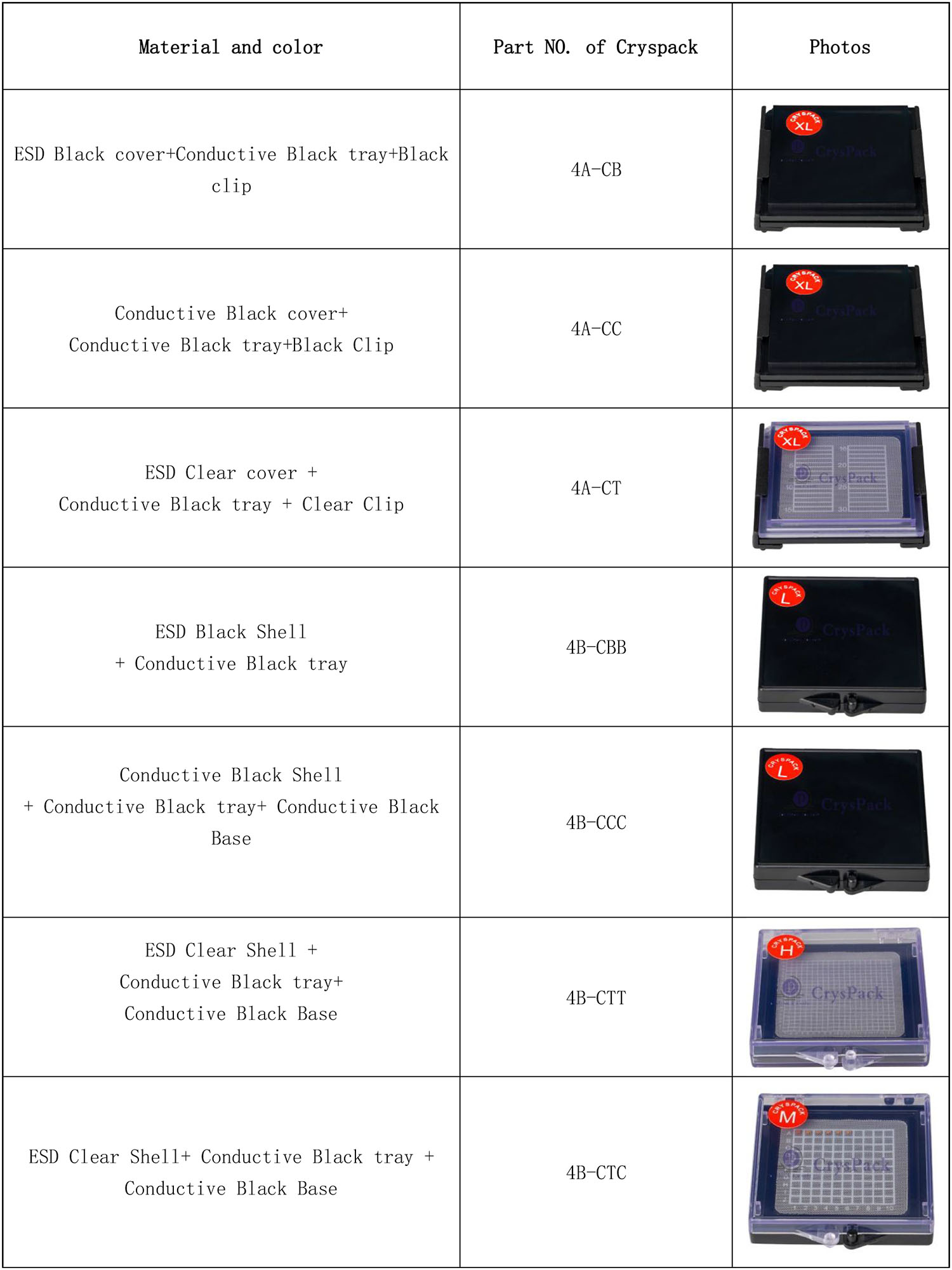

| Items | Technical parameters | |

| Size(inch) | 4 inch | |

| VR-4A series | A tray+ a cover+ a clip | |

| Color | VR-4A-CB | ESD black cover+ black conductive tray+ black conductive clip |

| VR-4A-CC | Black conductive cover+ black conductive tray+ black conductive clip | |

| VR-4A-CT | ESD clear cover+ black conductive tray+ clear/black clip | |

| Mesh size | 16,33、76、103、137、195 | |

| Print pattern | 10*10; 4*30;(Custom grid is acceptable) | |

| Color of gel film | Clear | |

| Retention Level | XL, L, M, H,HH | |

FAQS*

We provide comprehensive pre-sales and after-sales services.

-

Can we order goods from you directly?

Yes, we look forward to receiving your order. However, please note our minimum purchase quantitly. If you require smaller quantities we will be happy to arrange an individual delivery. We would be delighted to assist you.

-

Will it make my life better? Why?

Of course, The products we produce are environmentally friendly and harmless, with various styles.

You can also go to our Help Center