Perfect Product Transportation: 3D Membrane Box Solution

2024.10.28 / By hqt

When shipping a fragile item, it’s natural for a sense of worry to accompany thoughts of its journey. Yet, with the rise of innovative solutions like the 3D membrane box, that concern quickly gives way to confidence—confidence that what is sent will arrive unharmed, untouched by scratches, dust, or any unintended damage. In the fast-paced and ever-changing world of product transportation, especially when it comes to delicate items like dental tools, retainers, or advanced electronics, the flaws of traditional packaging have become increasingly clear.

As industries continue to expand, driven by the need for precision handling of sensitive goods, the outdated methods of packaging struggle to keep pace. It’s obvious that major improvements are necessary to address the modern demands of transportation and protection. This is where the 3D membrane box steps in—offering not only superior protection but also unparalleled convenience, setting a new standard in packaging technology.

Challenges in Product Transportation and Protection

Transporting delicate, highly sensitive items—whether dental tools, electronic components, or medical devices—brings specific challenges. These products are easily damaged by scratches, dust, impacts, or mishandling during their journey. While traditional packaging may work for bulkier goods, it often falls short in protecting fragile items. The result? Breakage, contamination, and costly returns or replacements.

In fields like healthcare and dentistry, for example, tools such as tweezers, picks, and retainers require not only careful handling but also sterility and full functionality when they arrive. However, standard packaging, lacking suspension or adequate protective features, allows these items to shift in transit, which increases the risk of harm or contamination. Moreover, its bulky design wastes space, leading to higher shipping costs and inefficient storage, further complicating logistics. It’s clear that these industries need a more advanced packaging solution to keep up with evolving transportation demands.

Why Traditional Boxes Need an Update

Although traditional packaging has served many industries for decades, it no longer meets the demands of a world where precision tools and fragile items are increasingly common. Several key issues highlight why a shift to more advanced solutions, like the 3D membrane box, is necessary.

Inadequate Protection: The use of basic padding materials, such as foam, in conventional packaging often proves insufficient. These materials can shift or compress during transit, leaving what’s inside vulnerable to movement-related damage. This becomes especially problematic when dealing with sensitive tools or electronics, as even a small impact can cause irreparable harm.

Lack of Visibility: Opaque packaging makes it difficult to identify what’s inside without opening it, which leads to unnecessary handling. This is particularly risky in medical settings, where hygiene is critical, and excessive contact increases the likelihood of contamination or accidental damage.

Space Inefficiency: Most traditional packaging is either too large or too small for the items it holds, resulting in wasted space. This inefficiency not only drives up shipping costs but also limits businesses from storing or transporting multiple items effectively.

Limited Durability: Cardboard and basic plastic boxes degrade over time, especially when exposed to environmental conditions or frequent handling. This leads to costly replacements and unreliable long-term storage.

Considering these limitations, it’s clear that the packaging industry needs a solution offering better protection, improved space efficiency, and greater durability—all qualities that the 3D membrane box delivers.

How the 3D Membrane Box Solves Transportation Problems

The 3D membrane box stands out as a cutting-edge solution to the complex challenges associated with transporting fragile items. Its innovative design directly tackles the limitations of traditional packaging, ensuring that products not only reach their destination in pristine condition but also that storage space is optimized and shipping costs are kept to a minimum.

Membrane Construction for Superior Protection

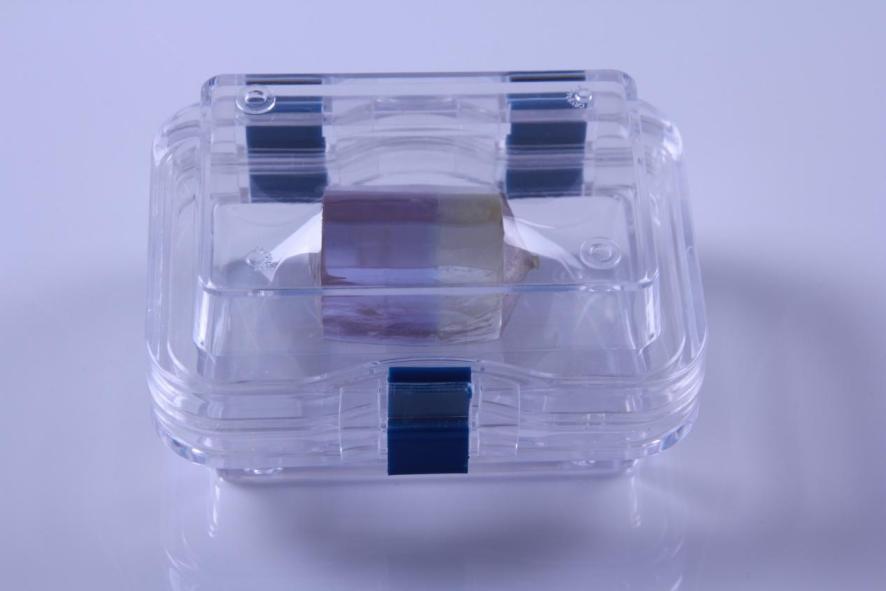

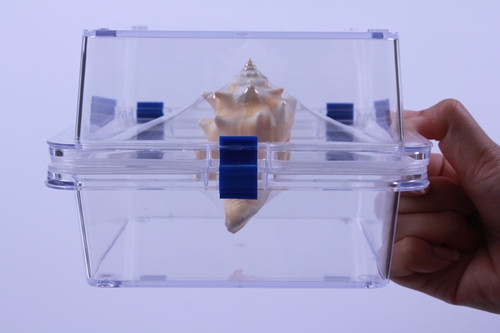

What sets this packaging apart is its revolutionary membrane, both transparent and highly durable. It suspends items securely in place, offering superior protection by preventing movement during transit and shielding them from scratches. Whether it holds delicate dental tools, sensitive electronics, or precision medical instruments, the membrane’s firm grip ensures they stay protected from impacts, dust, and other elements that could threaten their condition.

Compact Design with a Large Storage Capacity

Despite its small size, the case is cleverly designed. Holds a variety of items in one space-saving unit. This enables businesses to store and ship multiple items in one compact package. This not only reduces shipping costs but also increases organizational efficiency. Industries such as healthcare and electronics, which often have limited space, benefit greatly from this high-capacity yet compact solution. Precision processing is possible without sacrificing valuable storage space.

Transparent Construction for Easy Identification

One of its most appealing features is the transparent build, enabling quick identification of contents without the need to open it. In medical environments, this transparency is particularly advantageous, helping maintain hygiene standards by reducing unnecessary handling. Similarly, industries dealing with many small components appreciate the convenience of seeing what’s inside at a glance, speeding up operations and reducing the likelihood of errors.

Hinged Lid with a Secure Clasp

The 3D membrane box comes with a hinged lid and a safety clasp. This prevents accidental spills and ensures that the contents remain securely closed during transport. For professionals in the medical or dental field, where sterility and protection are of utmost importance, this extra layer of security gives them peace of mind. Because they know their tools will remain intact and free from contamination.

Why Choose Cryspack? Your One-Stop Solution

When it comes to selecting the right supplier for your 3D membrane box needs, Cryspack is a leader in the precision packaging field. With a global reputation for excellence and a commitment to quality, Cryspack is the trusted choice for over 1,000 customers around the world. From custom packaging solutions to fast and reliable service, Cryspack offers everything businesses need to protect their sensitive products.

Custom Solutions for Unique Needs

Cryspack is not just a one-size-fits-all provider. The company offers a wide range of custom packaging solutions, including membrane boxes, gel sticky boxes, vacuum release trays, and vacuum release boxes. Whatever your industry or specific packaging requirements, Cryspack has the expertise to create a solution that fits your needs. Their approach is centered on flexibility, ensuring that every customer gets a packaging solution tailored to their unique specifications.

A Commitment to Quality and Certification

Cryspack has built its reputation on a foundation of quality. The company adheres to the strictest international standards, with all products meeting EU ROHS and REACH certification requirements. In addition to these certifications, Cryspack’s commitment to quality is exemplified by its ISO 9001 certification, which ensures that every item produced meets rigorous quality control standards. This dedication to excellence means that customers can rely on Cryspack products to provide the protection their goods need.

An Industry Leader with Proven Success

With over 1,000 active customers, Cryspack is a global leader in precision packaging. Since its establishment in 2005. The company has been providing innovative solutions to industries including semiconductor and optoelectronics, telecommunications, automotive and medical devices. Cryspack’s innovative R&D team continues to push the limits of packaging. And its responsive sales network ensures customers always receive timely and effective support.

A History of Innovation

Since its inception, Cryspack has been at the forefront of packaging innovation. By continuously developing new products and improving existing products. The company has become a preferred supplier to businesses that require reliability and top-notch service. The development of the 3D membrane box is just one example of Cryspack’s ability to anticipate industry needs and create solutions that not only meet but exceed expectations.

Products Beyond the 3D Membrane Box

While the 3D membrane box is a flagship product, Cryspack offers a diverse range of packaging options. These solutions include gel boxes for the safe handling of sensitive materials, vacuum boxes for storing items that require a sealed environment, and wafer boxes designed specifically for the semiconductor industry. The versatility of these solutions allows Cryspack to serve a variety of industries. Each industry has its own unique challenges and requirements.

Cryspack: Your Trusted 3D Membrane Box Supplier

As a leading name in precision packaging, Cryspack has pioneered the development of the 3D membrane box, addressing the needs of industries requiring advanced packaging solutions for fragile and high-value items. With a customer base exceeding 1,000 clients worldwide, Cryspack offers customizable packaging solutions, including membrane boxes and vacuum release trays, all produced under the strictest quality control measures and certified to ISO 9001