Can Antistatic Plastic Packaging Box Reduce Damage Costs in Your Industry?

2024.10.31 / By hqt

Can Antistatic Plastic Packaging Reduce Damage Costs in Your Industry?

In the fast-paced world of modern manufacturing, protecting delicate components during shipping and handling is critical. This is especially true in industries such as semiconductors, optoelectronics, and telecommunications, where even the slightest damage to sensitive parts can result in costly production delays and expensive repairs. One of the key solutions to this problem is antistatic plastic packaging. But how exactly can it help reduce damage costs and improve efficiency in your industry? Let’s dive into the benefits and explore why businesses are turning to antistatic packaging as a best-in-class solution.

The Die Migration Problem: A Hidden Cost

Understanding Die Migration

Die migration is a common and costly problem faced by industries that handle microelectronic components, especially in semiconductor manufacturing. When dies, which are small, delicate chips, are packaged in traditional waffle packs, they are prone to shifting or escaping from their designated pockets. This phenomenon, known as COOP (Component Out of Pocket), often results in the die moving into adjacent pockets, flipping, or becoming lodged between the pockets, causing damage and leading to significant financial loss.

Consequences of Die Migration

The consequences of die migration extend beyond just the physical damage to the components. When dies shift and get damaged, manufacturers face numerous issues:

Component Damage and Scrap: Damaged dies result in unusable components, leading to material wastage.

Increased Labor Costs: Workers must spend additional time inspecting, repackaging, and reordering damaged components.

Production Delays: Manufacturing is disrupted due to yield loss and equipment downtime.

Higher Machine Downtime: Pick-and-place machines, used for automated die placement, face reduced utilization due to die misalignment and flipping.

Compromised Quality: If a defect caused by die migration isn’t detected early, it can lead to rework and troubleshooting costs in higher assembly stages.

Ultimately, these issues increase manufacturing costs and negatively impact efficiency. This is where antistatic plastic packaging box comes into play, offering a modern solution to reduce such challenges.

The Root Cause: Why Traditional Packaging Fails

Old Solutions for New Problems

The primary reason for die migration lies in the outdated design of traditional packaging methods. Historically, waffle packs used to package dies were designed for thicker, more durable dies. However, as technology evolved, die sizes shrank significantly—dropping from hundreds of micrometers to tens of micrometers in thickness—without corresponding changes to the packaging standards. This size reduction made components more vulnerable to shifting and damage during transport and handling.

Material and Design Flaws

The packaging materials themselves also contribute to the issue. Waffle packs and trays made from materials such as carbon-loaded polypropylene or ABS have warpage specifications that increase the likelihood of die movement. Misaligned or warped trays, irregular deformation, or improper lid usage exacerbate the problem, creating escape paths for dies to migrate. Additional factors like operator error, worn clips, and non-woven polyethylene inserts only worsen the situation.

Identifying the True Costs

While manufacturers initially blamed handling errors for die migration, advanced tools such as X-ray and 3D measurement systems have provided a more comprehensive view of the problem. The real culprit lies in the entire end-to-end process of handling, packaging, transporting, and storing delicate semiconductor dies. With this understanding, the need for an updated packaging solution became evident—one that could both protect components and ensure static control during transit.

The Antistatic Solution: How It Reduces Manufacturing Costs

What is Antistatic Plastic Packaging Box?

Antistatic plastic packaging box is designed to prevent the buildup of electrostatic charges that can damage sensitive electronic components. These boxes are made from materials that can safely dissipate static electricity, providing a protective environment for the packaged items. The use of such packaging is crucial in industries dealing with semiconductors, medical devices, optoelectronics, and telecommunications, where the risk of electrostatic discharge (ESD) can result in costly product failure.

Addressing the Problem of Die Migration

The use of antistatic plastic packaging box directly addresses the problem of die migration. By minimizing the risk of static electricity buildup, these boxes prevent components from sticking to the tray surfaces or flipping within their pockets. Additionally, the improved design and material rigidity of antistatic boxes ensures that components remain securely in place during transport. This results in:

Reduced Component Damage: With dies safely contained and protected, the risk of physical damage or flipping is drastically reduced.

Decreased Labor Costs: Less time is spent on inspecting and repackaging components, allowing workers to focus on more value-added tasks.

Improved Equipment Utilization: Automated pick-and-place machines can operate more efficiently with properly oriented dies.

Higher Quality Assurance: The consistency and reliability provided by antistatic packaging reduce the need for costly rework and troubleshooting.

In short, antistatic plastic packaging is a proactive approach that saves time, money, and resources across the entire manufacturing process.

Cryspack: Your One-Stop Antistatic Packaging Solution

Who Is Cryspack?

Cryspack is a leading global supplier of precision packaging solutions. Founded in 2005, the company has built a reputation for providing innovative and reliable packaging that meets the high demands of industries such as semiconductors, telecommunications, medical devices, and automotive. With over 1,000 active customers worldwide, Cryspack is known for its dedication to quality and customer service.

Cryspack’s Innovative Packaging Solutions

Cryspack offers a wide range of antistatic packaging solutions tailored to meet the needs of businesses handling sensitive components. Some of Cryspack’s most popular products include:

Membrane Boxes: These are designed for storing and shipping fragile devices, providing cushioning and shock absorption.

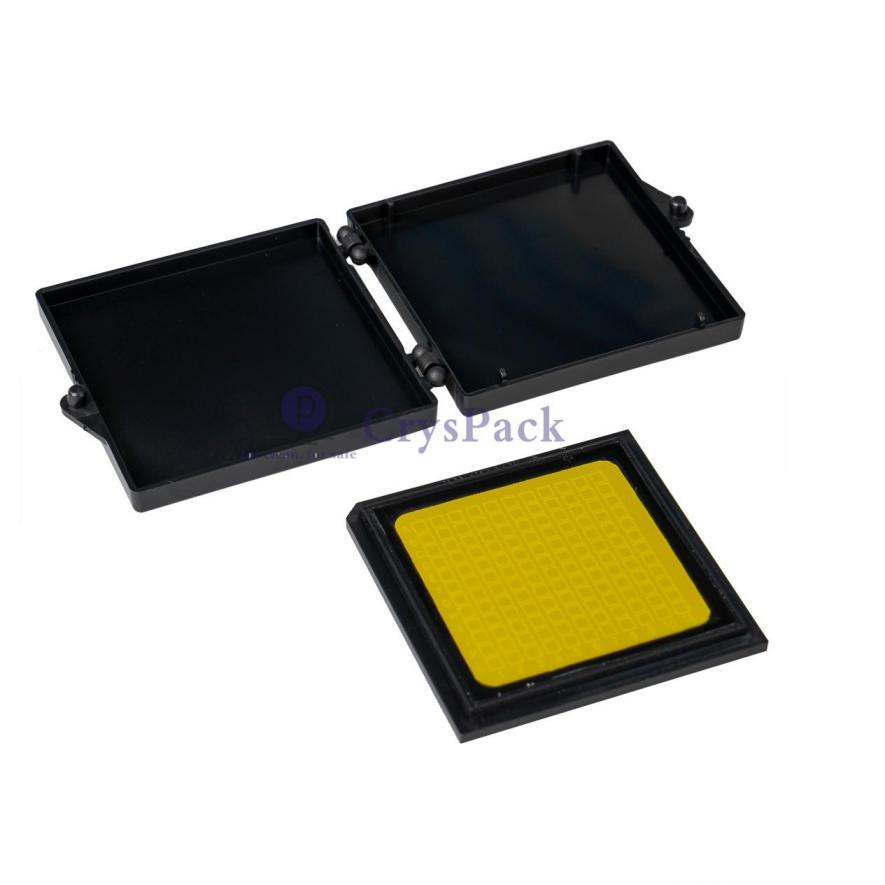

Gel Sticky Boxes: Ideal for small, delicate components that need to stay in place during transport.

Vacuum Release Trays and Boxes: Perfect for handling and transporting semiconductor wafers and other sensitive parts, with secure vacuum sealing.

Wafer Boxes: Custom-designed to safely store and transport delicate wafers used in semiconductor manufacturing.

All of Cryspack’s packaging solutions are compliant with EU ROHS and REACH certification standards, ensuring that their products are safe, reliable, and environmentally responsible.

Why Choose Cryspack?

What sets Cryspack apart is its comprehensive approach to customer service. Their innovative R&D team works closely with clients to develop custom solutions that meet specific needs, whether it’s protecting fragile components or streamlining automated handling processes. Cryspack’s focus on quality and attention to detail is reflected in its quality management system, ensuring that every product meets the highest standards. Their fast-response sales network further guarantees a smooth and satisfactory purchasing experience.

Conclusion: The Future of Industrial Packaging

As industries continue to advance and components become smaller and more sensitive, traditional packaging solutions are no longer sufficient to meet the demands of modern manufacturing. Antistatic plastic packaging box offers a significant upgrade, reducing the risks of die migration, electrostatic discharge, and component damage. By investing in antistatic packaging from trusted suppliers like Cryspack, businesses can improve efficiency, reduce costs, and ensure the integrity of their products throughout the supply chain.

If your business is looking for a reliable partner in antistatic packaging, Cryspack provides the expertise, custom service, and innovative solutions you need to stay ahead in today’s competitive market.