Guide to Gel Sticky Box: Secure and Versatile Device Handling

2024.10.29 / By hqt

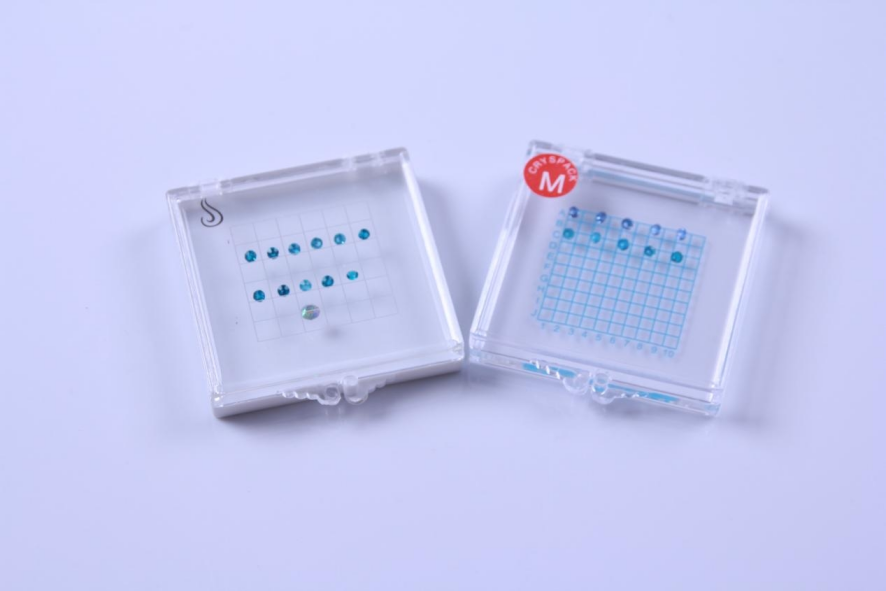

When it comes to safely handling and shipping delicate devices, especially in industries like semiconductors, optoelectronics, and telecommunications, reliable packaging solutions are essential. Imagine shipping a wafer-thin, fragile device only to find it damaged upon arrival due to inadequate packaging. To prevent such issues, Cryspack, a leading name in precision packaging, offers its innovative Gel Sticky Box series, designed to securely hold devices during transportation and handling.

In this guide, we’ll explore the features, applications, and best practices for using Cryspack’s Gel-Box, Gel-Tray, and Gel-Slide products, ensuring that your delicate components remain safe and intact. Let’s delve into the details!

What Is a Gel Sticky Box and Why Does It Matter?

The Gel Sticky Box (AD Series), along with its counterparts Gel-Tray (BD Series) and Gel-Slide (CD Series), is a “pocketless” carrier designed to hold delicate devices securely using a special Gel surface. Unlike traditional methods that use foam or clips, these Gel surfaces provide a highly versatile and safe solution to secure items during transportation or handling. The Gel surface comes in varying levels of tack, known as Gel Retention Levels, which allow for customization based on the size, shape, and fragility of the devices.

Why Does the Gel Surface Work So Well?

The secret behind the Gel’s effectiveness lies in its adhesive-like properties, which create surface contact with the device, keeping it in place. However, it doesn’t act like glue—it provides enough grip to hold items but allows for easy removal when needed by applying a twist or peel motion. This is crucial for ensuring that devices are both securely held in place and easily removed without damage.

Versatile Applications Across Industries

Cryspack’s Gel Sticky Boxes have applications in various industries where sensitive components require careful handling. From semiconductor wafers to medical devices, the Gel surface can accommodate a wide range of products. With over 1,000 customers worldwide, Cryspack has become a trusted name for ensuring that advanced technologies are transported without risk of damage.

The Gel Sticky Box Series Explained

Cryspack’s Gel Sticky Box lineup consists of three main series. Each has unique features suited to different applications.

The Gel-Box Series:

The Gel-Box series features plastic hinged boxes with a proprietary Gel coating applied to the bottom. These boxes come in various sizes, ranging from 1″ x 1″ to 7″ x 5″. The Gel coating securely holds devices in place, making them ideal for shipping and handling delicate items.

The Gel-Tray Series:

For those who need more flexibility, the Gel-Tray Series offers a removable option. It features a 2″ x 2″ Gel-coated plastic tray that can be removed from the hinged box. This version is ideal for applications where the Gel surface might need to be replaced or when handling different sizes of devices.

The Gel-Tray Series:

For an even more delicate touch, the Gel-Tray Series features a Gel-coated glass plate, offering superior flatness and minimal distortion. This series is perfect for ultra-thin or fragile devices, such as wafers or optical components, where precision and gentle handling are paramount.

Choosing the Right Gel Retention Level

Selecting the appropriate Gel Retention Level (or tack level) is critical for the successful use of a Gel Sticky Box. The Retention Level determines how much holding force the Gel applies to the device, balancing secure handling with easy removal.

Factors to Consider When Selecting the Gel Retention Level

There’s no one-size-fits-all solution when it comes to choosing the correct retention level. The right level depends on several factors:

Device Dimensions: Larger or heavier devices may require higher tack levels for secure handling.

Surface Roughness: Devices with smoother surfaces typically need less tack, while rougher surfaces may require a higher retention level.

Material Type: Some materials may adhere better to certain Gel retention levels than others.

Balancing Holding and Unloading Force

While it’s tempting to opt for the highest retention level for maximum holding power, this can lead to issues during device unloading. The key is to find a balance between sufficient holding force and easy removal. For very fragile devices, Cryspack offers a Vacuum Release (VR) Series, which might be a better fit.

Best Practices for Device Handling with Gel Sticky Boxes

Now that we’ve covered the basic features and applications of Gel Sticky Boxes, let’s dive into best practices for device handling, including loading, holding, and unloading.

Device Loading Guidelines

Devices should be loaded onto the Gel surface using standard tools such as tweezers or vacuum pick-up tools. It’s important to apply slight downward force to ensure good surface contact between the device and the Gel. The device should remain on the Gel for at least one minute before transportation to allow for adequate adhesion.

When handling fragile devices, extra care must be taken to avoid damaging the Gel surface or the device itself.

Gel Holding Force Test

To verify that the selected Gel Retention Level is sufficient, a simple holding force test can be performed. Close the carrier and gently tap the corner against a hard surface. This test simulates the Gel’s ability to hold the device during typical shipping environments. For more severe testing, drop tests from one meter can be conducted after allowing the device to rest on the Gel surface for a few minutes.

If the device shifts during the test, consider increasing the Gel contact time or selecting a higher retention level.

Device Unload Evaluation Test

When it’s time to remove the device from the Gel, use either tweezers or your hands. Avoid pushing the device into the Gel, as this can increase unloading forces and damage the device. If removal proves difficult, a lower retention level should be tested. For more fragile devices, Cryspack’s Vacuum Release (VR) products may be a better choice.

Why Choose Cryspack for Gel Sticky Boxes?

Cryspack stands out as a leading supplier in the field of precision packaging for several reasons.

Custom Solutions and Free Quotes

Cryspack offers a range of customizable packaging solutions, including Gel Sticky Boxes, membrane boxes, vacuum release boxes, and vacuum release trays. Customers can request free quotes, and the company’s Product Selection Wizard (PSW) helps users choose the perfect product based on their specific needs.

Commitment to Quality

With a quality policy that focuses on today’s quality being tomorrow’s market, Cryspack emphasizes reliable products and excellent customer service. The company is certified under EU ROHS and REACH standards, ensuring compliance with environmental and safety regulations.

Trusted by 1,000+ Customers Worldwide

Since its founding in 2005, Cryspack has earned the trust of over 1,000 active customers worldwide. With its innovative packaging solutions, the company has become a go-to choice in industries such as semiconductors, medical devices, telecommunications, and automotive.

Conclusion: Safe and Versatile Handling with Gel Sticky Boxes

Cryspack’s Gel Sticky Boxes offer an innovative and reliable solution for safely handling and shipping delicate devices. With the right Gel Retention Level, users can securely transport their components while ensuring easy unloading without damage. By following best practices and leveraging Cryspack’s expertise, businesses can protect their valuable technologies from the risks of handling and transportation.

Whether you’re dealing with fragile semiconductors, medical instruments, or sensitive telecommunications equipment, Cryspack’s versatile and customizable packaging solutions are designed to meet your needs. Explore the wide range of Gel Sticky Boxes, trays, and slides to keep your devices safe and secure every step of the way.