Why Are Vacuum Release Trays Essential for Fragile Device Handling?

2024.11.25 / By hqt

In today’s fast-paced, technology-driven world, ensuring the safe transport and handling of delicate components like silicon wafers is crucial. Imagine transporting ultra-thin, highly sensitive devices across long distances without a hitch. Cryspack’s vacuum release trays make this possible, blending efficiency with superior protection. This article delves into the remarkable features of Cryspack’s vacuum release trays, particularly the VR-A and VR-B series, and identifies the top five international markets with high demand for these products.

What Are Vacuum Release Trays?

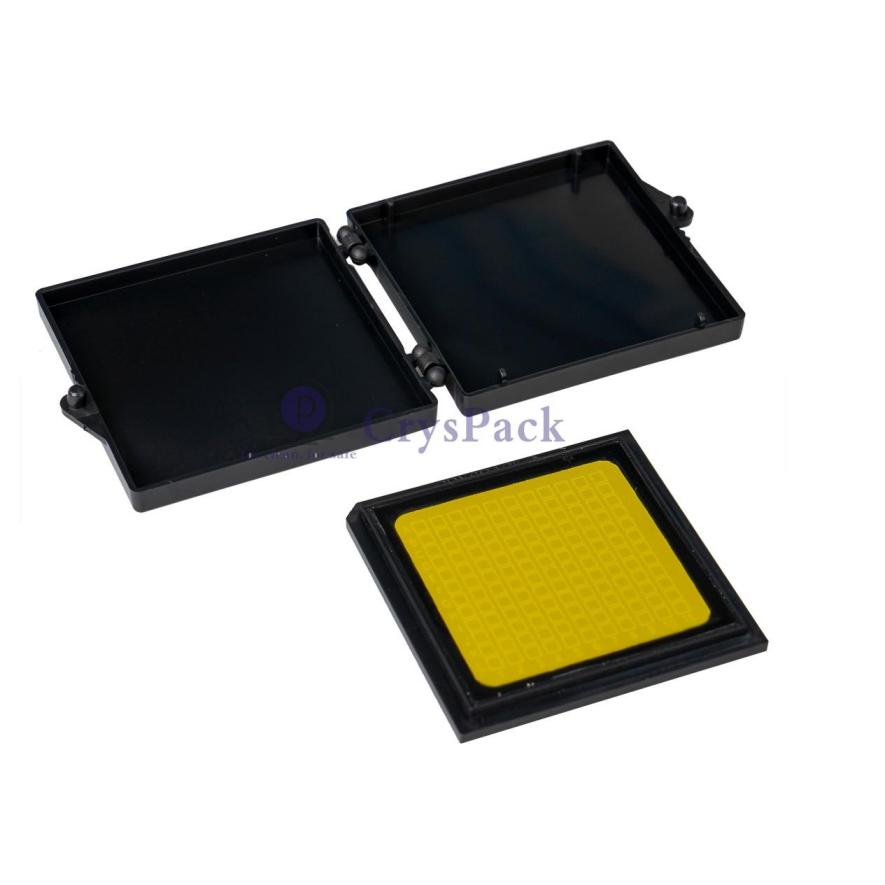

Vacuum release trays are specialized containers designed to hold and transport fragile items, such as silicon wafers, securely. Using patented vacuum technology, these trays offer a dual benefit: they secure the items in place, minimizing movement during transport while allowing quick release when the products need to be accessed. Cryspack, a prominent supplier from China, provides two series of vacuum release trays: the VR-A series (which includes a vacuum release tray, cover, and clip) and the VR-B series (comprising a vacuum release tray and a hinged box). Both are ideal for the transport, handling, and processing of extremely delicate devices.

Key Features of Cryspack’s Vacuum Release Trays

Dynamic Retention

Cryspack’s vacuum release trays are built with dynamic retention technology. This feature stabilizes devices, securing them during transit while ensuring swift access upon arrival. For businesses managing fragile products, such as silicon wafers or other thin materials, dynamic retention is a game-changer, reducing the risk of damage during handling.

Customizable Configuration

Cryspack’s trays are highly customizable, offering various tray sizes, retention levels, and mesh geometries. This level of customization enables companies to select the perfect tray for their specific requirements, aligning closely with the wafer size and sensitivity of the product.

Exceptional Particle Protection

Maintaining product purity is vital when handling sensitive devices. Cryspack’s vacuum technology effectively isolates the items from particulates, safeguarding them from contamination and preserving the product’s quality.

Increased Efficiencies

With Cryspack’s vacuum release trays, companies benefit from shorter production cycles and increased productivity, thanks to the tray’s design, which streamlines the process of placing and retrieving parts. This results in smoother, more efficient handling that reduces labor time and minimizes human intervention.

Data-Driven Design

Cryspack’s vacuum release trays are the result of extensive testing and data-driven design. Every feature is optimized for performance, reliability, and quality, offering a top-notch solution for companies worldwide.

Top 5 Countries to Target for Vacuum Release Trays

For a Chinese supplier like Cryspack, identifying high-demand international markets is essential for expanding the reach of their vacuum release trays. Based on market demand, trade relationships, economic indicators, and technology adoption rates, the following five countries are prime targets for Cryspack’s products.

1. United States

Demand for Advanced Technology & Innovation

As the world’s largest semiconductor market, the United States has a high demand for specialized equipment and handling solutions for delicate electronic components. In 2022, the U.S. semiconductor industry alone generated over $258 billion in revenue, highlighting a significant opportunity for suppliers of vacuum release trays to serve companies engaged in manufacturing and research.

Trade and Investment Opportunities

China and the U.S. have a complex trade relationship but remain critical trading partners. Many American companies rely on imported technology and components from China, making the U.S. a strategic choice for Cryspack. The demand for protective solutions for sensitive devices will likely keep growing in this region.

2. Germany

A Hub for High-Tech Manufacturing

Germany, known for its engineering prowess and emphasis on precision, is a major player in Europe’s semiconductor and electronics industry. With companies like Infineon Technologies leading the semiconductor sector, there is a strong demand for high-quality handling and transport solutions for delicate components. Germany’s annual semiconductor market revenue reached approximately $11 billion in 2022, underlining its potential for Cryspack’s offerings.

Strong Trade Relations with China

China and Germany have established a robust trade relationship, and Germany’s industrial sector often looks to China for cost-effective, high-tech products. This relationship facilitates easier entry for Chinese products into the German market.

3. South Korea

Growing Semiconductor Industry

South Korea is home to major semiconductor giants like Samsung and SK Hynix, which together make up a significant portion of the global memory chip market. In 2022, South Korea’s semiconductor industry generated around $110 billion in revenue. The need for specialized trays that protect wafers and fragile devices during manufacturing is substantial in this highly competitive market.

Geographic Proximity and Established Trade Links

South Korea’s proximity to China, coupled with well-established trade relationships, makes it an ideal target for Chinese suppliers like Cryspack. As Korean companies continue to innovate in memory chips and other high-tech components, demand for reliable, protective transport solutions is set to increase.

4. Japan

Demand for High-Quality Transport Solutions

Japan, a leader in electronics and semiconductor production, has a substantial demand for handling solutions for sensitive devices. Companies such as Sony and Toshiba are at the forefront of the technology sector, and Japan’s semiconductor industry is expected to reach $40 billion by 2025. Given Japan’s high standards and focus on precision, Cryspack’s vacuum release trays are well-suited to this market.

Trade Ease and Cultural Compatibility

China and Japan maintain strong trade ties, with China being one of Japan’s top trading partners. Japanese companies often prefer to source specialized technology and components from China due to geographic proximity, cost benefits, and established trade agreements.

5. Taiwan

Global Semiconductor Manufacturing Hub

Taiwan is a crucial player in the global semiconductor supply chain, with companies like TSMC dominating the market. Taiwan’s semiconductor exports exceeded $118 billion in 2022, making it a prime market for suppliers of vacuum release trays. Companies require high-quality, dependable solutions for handling delicate products, and Cryspack’s products are an excellent fit for these requirements.

Favorable Trade and Geographic Advantages

China and Taiwan share a close geographic location and strong trade links, despite political complexities. Taiwanese companies often source materials and equipment from Chinese suppliers due to their accessibility, competitive pricing, and reliable quality, positioning Cryspack favorably within this market.

How Cryspack Can Cater to These Markets

Tailored Product Offerings

Cryspack’s VR-A and VR-B series vacuum release trays offer the versatility required to cater to diverse market needs. From offering trays in various sizes and configurations to adapting retention levels and mesh geometries, Cryspack can tailor its products to meet the specific demands of each target country.

Leveraging Trade Relationships and Proximity

Countries like South Korea, Japan, and Taiwan benefit from proximity to China, which allows Cryspack to offer competitive pricing and faster delivery times. Leveraging these trade relationships can strengthen Cryspack’s position in these markets, where high-tech industries demand precise, effective solutions.

Ensuring High Standards and Customization

Cryspack’s commitment to quality aligns with the high standards expected in markets like Germany and Japan. By highlighting the customization and reliability of their products, Cryspack can appeal to clients in these regions who prioritize high-performance solutions for fragile device handling.

Conclusion

Vacuum release trays play a vital role in the transport and handling of delicate devices, with Cryspack’s products standing out for their quality, customization, and efficiency. By targeting key markets like the United States, Germany, South Korea, Japan, and Taiwan, Cryspack is well-positioned to meet the growing global demand for high-quality transport solutions in the semiconductor and electronics sectors. The company’s data-driven design and focus on customer-specific needs make Cryspack’s vacuum release trays an invaluable asset in today’s technology-driven world.