Customizing Your ESD Gel Box with Cryspack

2024.07.09 / By hqt

In the realm of electronic components and semiconductor devices, safeguarding against Electrostatic Discharge (ESD) is paramount to ensuring their reliability and longevity. Cryspack, a leading manufacturer in the field, offers an innovative solution with their ESD gel box. This product serves as a protective carrier designed specifically for storing and transporting sensitive devices that are susceptible to ESD damage. By employing advanced materials and design, Cryspack addresses the critical need for secure handling and storage in both manual and automated environments.

Understanding Electrostatic Discharge (ESD) Risks

Electronic components, especially integrated circuits (ICs) and semiconductor devices, are highly vulnerable to damage from ESD. ESD occurs when two objects with different electrical potentials come into contact or near proximity, resulting in a sudden flow of electricity. This discharge can potentially disrupt or permanently damage sensitive electronic components, leading to costly failures and decreased product reliability. Manufacturers must implement stringent ESD protective measures throughout the production, handling, and transportation phases to mitigate these risks.

Cryspack’s ESD gel box provides a robust solution to shield fragile components from ESD hazards during various stages of their lifecycle. The design incorporates a static dissipative carrier that effectively neutralizes static charges, thereby safeguarding the enclosed devices from potential damage.

Features and Construction of Cryspack ESD Gel Box

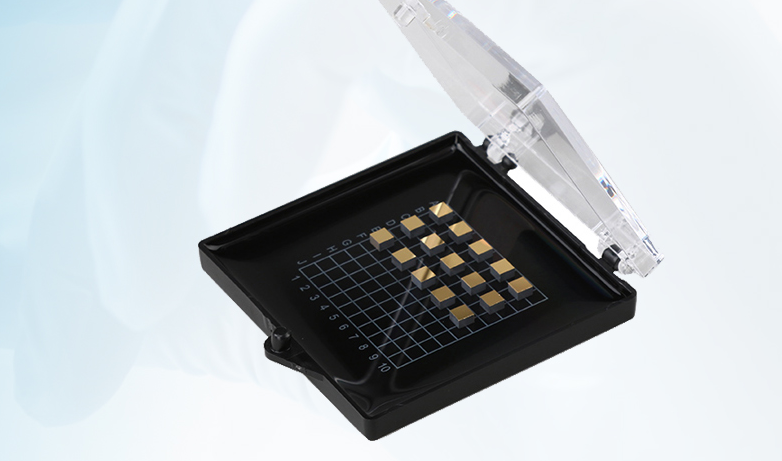

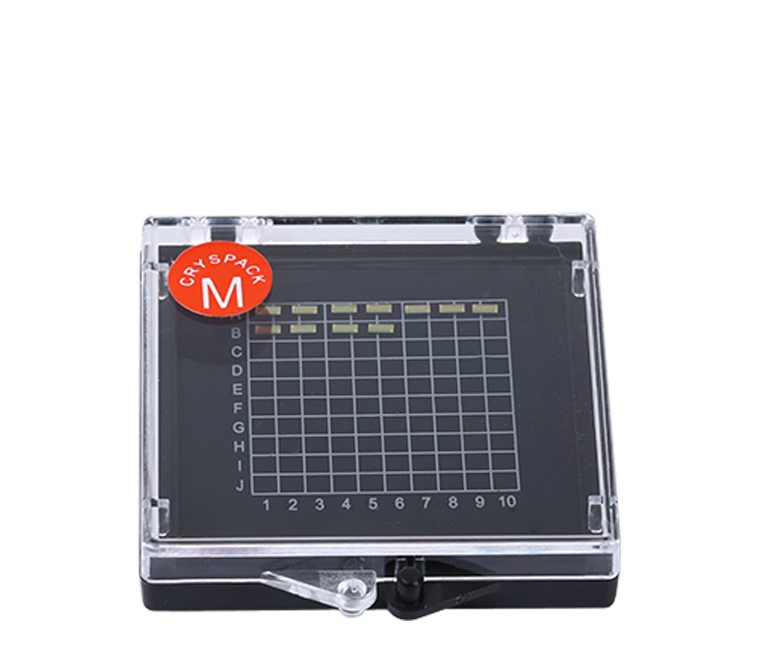

The ESD gel box from Cryspack is engineered with precision and attention to detail, ensuring optimal protection and ease of use for electronic components. It consists of a static dissipative box with transparent elastic membranes securely mounted on the top and bottom. This construction not only provides visibility of the enclosed device but also ensures a snug fit that prevents movement during transit or handling.

The materials used in Cryspack’s ESD gel box exhibit exceptional properties required for ESD-sensitive applications. Both the box and the membranes feature a surface resistivity of ≤ 10^11 ohms/square, effectively dissipating static charges to minimize the risk of ESD-related failures. This characteristic makes the gel box suitable for a wide range of electronic components, including bare dies and small-scale devices used in industries such as telecommunications, automotive electronics, and medical devices.

Applications and Benefits in Electronic Manufacturing

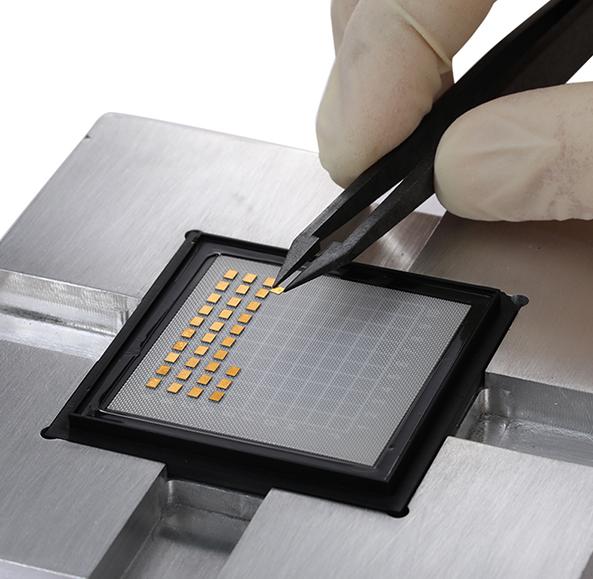

The versatility of Cryspack’s ESD gel box extends across various stages of electronic manufacturing processes. From initial assembly and testing to final packaging and shipment, the gel box ensures consistent protection against ESD-induced failures. Its design facilitates easy integration into automated pick-and-place systems, allowing for efficient handling and processing of delicate components without compromising on safety or reliability.

Electronic manufacturers benefit from the practical advantages offered by Cryspack’s ESD gel box. Its static dissipative properties reduce the need for additional ESD protective measures, thereby streamlining production workflows and minimizing operational costs. Moreover, the gel box’s compatibility with vacuum-based offloading systems enhances productivity by enabling rapid and secure retrieval of components during assembly and testing procedures.

Design and Material Innovation

At the core of Cryspack’s ESD gel box is a commitment to innovation and quality. The design incorporates a conductive tray integrated with a static dissipative polyurethane film, ensuring robust protection against electrostatic charges. This combination of materials not only enhances the durability of the gel box but also maintains its effectiveness over extended periods of use. Cryspack offers customization options in terms of box sizes and film tack levels, catering to specific requirements of different electronic components and assembly environments.

The transparent elastic membranes used in the gel box conform precisely to the contours of the enclosed device, providing a secure hold that prevents shifting or damage during transit. This feature is particularly crucial for delicate components that require meticulous handling to maintain their integrity and functionality. By integrating advanced materials with ergonomic design principles, Cryspack has created a solution that meets the stringent demands of modern electronic manufacturing practices.

Environmental Considerations and Sustainability

In addition to its technical prowess, Cryspack prioritizes environmental sustainability in the production and usage of its ESD gel box. The materials used in manufacturing are chosen not only for their ESD protection capabilities but also for their eco-friendly attributes. By promoting durability and reusability, Cryspack contributes to reducing environmental impact by minimizing waste generation and resource consumption associated with disposable packaging solutions.

The gel box is designed to withstand repeated use without compromising on performance or safety, offering a cost-effective alternative to single-use packaging materials. This approach aligns with global efforts towards sustainable manufacturing practices and corporate social responsibility, reinforcing Cryspack’s commitment to environmental stewardship within the electronics industry.

Why Choose Cryspack for Your ESD Gel Box Needs?

Cryspack’s commitment to quality and innovation is exemplified in its comprehensive range of packaging solutions. From membrane boxes to vacuum boxes and specialized gel boxes, each product is crafted with precision and adherence to stringent international standards such as EU ROHS and REACH certifications. This dedication to quality extends to their ESD gel boxes, which are essential for protecting sensitive electronic components from the damaging effects of electrostatic discharge during shipping and handling.

Cryspack’s reputation as a trusted supplier is built on its perfect quality management system and an innovative R&D team that continually strives to enhance product performance and reliability. Their fast-response sales network ensures that customers receive prompt assistance and personalized service, making Cryspack a preferred choice for companies seeking robust ESD protection solutions.

Customization Options Available

Cryspack understands that not all electronic components are created equal, which is why they offer customizable options for their ESD gel boxes. Whether you require specific dimensions, additional features, or unique configurations to accommodate irregularly shaped or fragile devices, Cryspack can tailor their packaging solutions to meet your exact specifications.

Tailored Solutions for Different Industries

Cryspack’s ESD gel boxes find applications across a wide spectrum of industries including semiconductor, optoelectronic, microwave, telecommunications, medical, automotive, and more. Each industry presents unique challenges in terms of ESD protection and packaging requirements. Cryspack collaborates closely with customers to develop bespoke solutions that address these challenges effectively, ensuring that delicate components reach their destinations intact and fully functional.

Advanced Materials and Design

At the heart of Cryspack’s ESD gel boxes lies advanced materials and thoughtful design. The boxes are constructed using a combination of static dissipative materials and specialized gel coatings that provide a secure and stable environment for sensitive devices. This construction not only prevents electrostatic discharge but also cushions devices against physical shocks and vibrations during transit, further enhancing their reliability.

Compliance and Certification

All Cryspack products, including their ESD gel boxes, adhere to the highest standards of quality and safety. Compliance with EU ROHS and REACH regulations ensures that their packaging solutions are environmentally friendly and free from hazardous substances, making them suitable for global markets and diverse applications without compromising on performance or reliability.

Customer-Centric Approach and Support

Cryspack’s dedication to customer satisfaction is evident in their proactive support and commitment to continuous improvement. They offer comprehensive after-sales service, including product inspections and free replacements for any faulty items, demonstrating their confidence in the durability and performance of their ESD gel boxes.

Project Scenarios and Case Studies

Cryspack’s portfolio includes successful project implementations in various sectors such as opto-electronics, semiconductor manufacturing, and RF/wireless technologies. Each project showcases Cryspack’s expertise in providing tailored packaging solutions that meet specific industry requirements, ensuring optimal protection and reliability for sensitive electronic components.

Collaborative Partnership

Partnering with Cryspack means gaining access to a dedicated team of packaging experts who understand the nuances of ESD protection and packaging design. Their collaborative approach allows for seamless integration of customized solutions into existing manufacturing processes, optimizing efficiency and reducing operational costs associated with product damage or failures due to ESD.

Commitment to Innovation and Sustainability

Beyond meeting immediate packaging needs, Cryspack is committed to driving innovation and sustainability in the electronics packaging industry. Their ongoing research and development efforts focus on enhancing product performance while minimizing environmental impact. By choosing Cryspack as your ESD gel box manufacturer, you not only protect your valuable electronic components but also contribute to sustainable practices within your industry.

Conclusion

Cryspack’s ESD gel box represents a pinnacle of innovation and reliability in safeguarding electronic components against Electrostatic Discharge (ESD) risks. With its advanced design, static dissipative materials, and user-friendly features, the gel box ensures uncompromised protection during storage, handling, and transportation. Electronic manufacturers worldwide benefit from the operational efficiency and reliability afforded by Cryspack’s ESD gel box, making it an indispensable component in the quest for quality and longevity in electronic products.