Gel Sticky Box

2024.05.22 / By admin

Meta Descriptions

Discover CrysPack’s gel sticky box, ideal for safe storage of adhesive materials and other delicate items. Find solution for your needs.

Effortless Unloading: How Gel Sticky Box Simplifies Device Removal

Discover how Gel Sticky Box revolutionizes device handling with effortless unloading. Explore the seamless removal process and learn how CrysPack’s innovative technology simplifies device extraction for enhanced workflow efficiency.

Introduction to CrysPack: Revolutionizing Medical Device Packaging

1.1 CrysPack: Pioneering Innovative Solutions

In the realm of medical device packaging, one name stands out for its commitment to innovation and excellence: CrysPack. Established with a vision to revolutionize the way medical components are transported, processed, and stored, CrysPack has consistently pushed the boundaries of technology to deliver cutting-edge solutions that meet the evolving needs of the healthcare industry.

1.2 Unveiling the Revolutionary Gel Technology

At the heart of CrysPack’s groundbreaking solutions lies its innovative gel technology. Designed to secure medical components with utmost precision and care, this gel stands as a testament to CrysPack’s dedication to excellence in every aspect of its operations. But what exactly makes this gel technology so remarkable?

Understanding the Gel Composition and Functionality

2.1 Composition: The Science Behind the Gel

Delving into the intricacies of CrysPack’s gel technology reveals a proprietary highly crosslinked elastomer gel. Crafted with precision and expertise, this gel boasts a unique composition that sets it apart from conventional packaging materials. Its advanced molecular structure imbues it with exceptional strength and resilience, making it the ideal choice for securing delicate medical components during transit, processing, and storage.

2.2 Functionality: Cohesive Strength and Particle Minimization

The functionality of CrysPack’s gel technology is truly unparalleled. One of its most striking features is its cohesive strength, which enables it to firmly hold medical devices in place without the risk of slippage or displacement. This not only ensures the integrity of the components but also minimizes the generation of particles, thereby upholding the highest standards of cleanliness and safety.

2.3 Versatility: Adaptable to Diverse Needs

Moreover, CrysPack’s gel technology exhibits remarkable versatility, seamlessly accommodating small, lightweight, and delicate components. This technology ensures reliable protection and stability across a wide range of applications. Additionally, we offer customizable anti-static gel boxes tailored to meet specific needs. For instance, Gel-Pak provided a customer with an AD conductive Gel-Box product that uses a static dissipative (ESD) gel. This Gel-Pak product offered just the right amount of tack to secure the customer’s device during the manufacturing process while meeting the required ESD specifications.

Application of Gel Sticky Box Technology in Medical Device Packaging

3.1 Incorporating Gel into Packaging Solutions

The application of CrysPack’s gel technology in medical device packaging opens up a world of possibilities. From boxes and trays to slides and films, the versatility of this technology knows no bounds. By incorporating the gel into different types of packaging, CrysPack ensures that medical devices are not only securely held in place but also shielded from external factors that could compromise their integrity.

3.2 Securing Devices during Transit and Storage

One of the key benefits of CrysPack’s gel sticky box technology lies in its ability to securely hold medical devices in place during transit and storage. Whether it’s a short journey across town or a long-haul voyage across continents, healthcare providers can rest assured knowing that their valuable equipment is in safe hands. With CrysPack’s gel technology, the risk of damage or contamination is significantly reduced, allowing medical devices to reach their destination in pristine condition.

3.3 Enhancing Safety and Reliability

In an industry where precision and reliability are paramount, CrysPack’s gel sticky box technology emerges as a game-changer. By providing an extra layer of protection and security, this innovative solution not only safeguards medical components but also enhances the overall safety and reliability of the packaging process. With CrysPack’s gel technology, healthcare providers can focus on what matters most: delivering quality care to those in need.

Overview

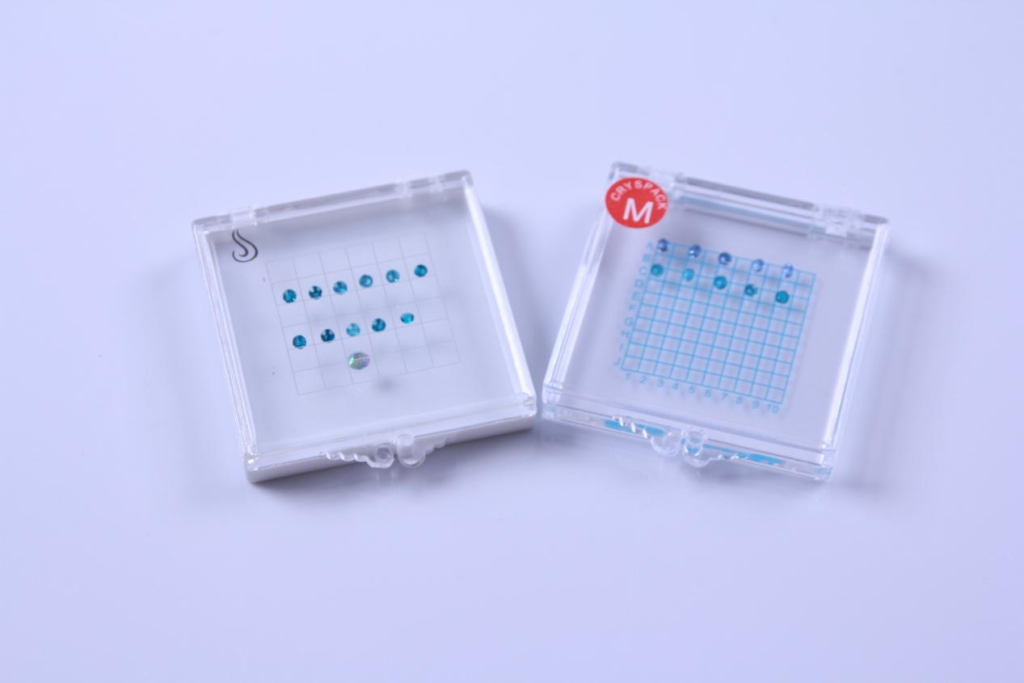

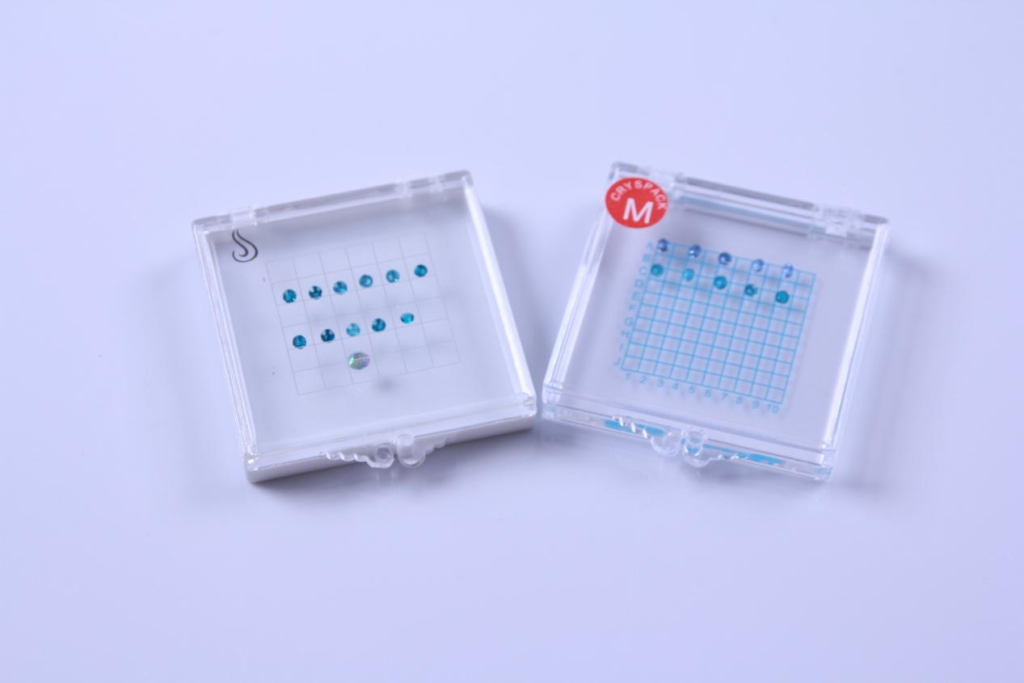

4.1 Innovative Design for Manual Applications

CrysPack presents its cutting-edge Gel Sticky Box Series Carriers, designed to revolutionize manual device handling applications. These carriers offer a seamless loading experience, accommodating devices through various methods such as vacuum pens, tweezers, or manual placement with fingers. Once loaded, devices are securely held in place by the Gel surface, ensuring stability during transportation and handling.

4.2 Flexible Unloading Mechanism

Unlike conventional methods, unloading devices from the Gel Sticky Box is effortless. By applying a simple twist or rotation motion, devices can be easily removed, thanks to the Gel’s unique holding strength properties. This flexibility ensures efficient workflow without the need for specialized tools, making it ideal for diverse production environments.

4.3 Tailored Gel Retention Levels

The Gel Sticky Box Series is available in a range of tack levels, referred to as Retention Levels, catering to various device types and surface finishes. This customization ensures optimal performance and compatibility, allowing users to select the most suitable tack level for their specific applications.

4.4 Versatile Product Range

CrysPack offers a diverse range of Gel Sticky Box products to meet different requirements. The AD Gel-Boxes feature a plastic hinged design with the Gel coating directly applied to the bottom, available in sizes ranging from 1” x 1” to 7” x 5”. For added flexibility, the Gel-Tray (BD Series) provides a removable Gel-coated plastic tray stored inside a hinged box, while the Gel-Slide (CD Series) offers a glass plate version of the Gel-Tray.

4.5 Enhanced Protection for Fragile Devices

For particularly delicate or thin devices, CrysPack recommends the CrysPack Vacuum Release (VR) Series tray. This specialized tray provides extra protection, ensuring the safe transportation and handling of fragile components, especially those less than 150µm in thickness.

Suggested Gel Retention Level (Holding Force)

5.1 Customized Retention Levels

Determining the appropriate Gel Retention Level (Xn) for specific devices is crucial for optimal performance. Factors such as device dimensions, surface roughness, and material type influence the required tack level. While selecting the highest tack level may seem beneficial for maximum holding force, finding the right balance between holding force and ease of device unloading is essential.

5.2 Evaluation Process

CrysPack recommends evaluating Gel samples to determine the optimal tack level for each device. This process ensures that the selected tack level provides sufficient holding force during shipping and handling while allowing for easy device unloading. The Gel Tack level must strike a balance between secure device retention and effortless unloading to enhance operational efficiency.

5.3 Performance Optimization

Achieving the optimum Gel Retention Level involves understanding the unique properties of each device. By carefully assessing factors such as device mass, surface roughness, and Gel contact area, users can optimize performance and minimize the risk of device damage or displacement during handling.

Device Loading Instructions

6.1 Efficient Loading Process

Loading devices onto the Gel surface is a straightforward process that aligns with standard production methods. Manual systems such as tweezers or vacuum pick-up tools are commonly used with Gel Sticky Box carriers. Applying slight downforce to the device ensures good surface contact with the Gel, facilitating secure retention during transportation.

6.2 Surface Contact Optimization

To maximize Gel holding strength, devices should typically remain mounted on the Gel surface for a minimum of one minute. However, the required time may vary based on factors such as device surface roughness, mass, and Gel retention level. Optimizing surface contact enhances stability and minimizes the risk of device displacement during handling.

6.3 Cautionary Measures

Care should be taken when using tweezers to avoid damaging the Gel surface. Additionally, excessive downward force during device loading should be avoided to prevent potential damage or increased unload forces during device removal.

Gel Holding Force Test

7.1 Quality Assurance Process

Verifying the selected Gel Tack level is crucial to ensure adequate holding force for loaded devices. The Gel holding force test involves tapping the CrysPack Carrier on a hard surface to evaluate holding strength. This simulated test replicates typical shipping and handling conditions, allowing users to assess the Gel’s effectiveness in securing devices.

7.2 Performance Evaluation

If any device position shifts during testing, adjustments such as allowing a longer waiting period for increased Gel contact area or evaluating a higher Gel Retention Level may be necessary. For large mass devices, additional testing, such as an upside-down position test, can further validate Gel holding performance over time.

Device Unload Evaluation Test

8.1 Efficient Unloading Process

Simulating the actual production environment, device unloading from Gel Sticky Box carriers is typically performed using tweezers or manual manipulation. Unlike vacuum pick-up tools, which may not work effectively due to the required twist or peel motion, manual unloading methods ensure seamless device removal without compromising Gel integrity. Optimizing Unload Forces

Minimizing downward force during device unloading is essential to prevent device damage or excessive unloading forces. If device removal proves difficult, adjusting the Gel Retention Level and repeating tests can help optimize unload performance while ensuring device safety and integrity.

8.2 Long-Term Storage Considerations

Conducting longer-term storage tests by leaving devices on the Gel surface for a minimum of 48 hours enhances surface contact and stability. This ensures maximum holding force and minimizes the risk of device displacement during extended storage periods.

Conclusion: A New Era in Medical Device Packaging

As the healthcare landscape continues to evolve, the demand for innovative packaging solutions has never been greater. In this regard, CrysPack stands at the forefront, leading the charge with its revolutionary gel sticky box technology. By combining cutting-edge science with unwavering dedication, CrysPack is shaping a new era in medical device packaging—one where safety, reliability, and excellence reign supreme. With CrysPack’s gel technology, the future of healthcare packaging has never looked brighter.